2022 Amazon Restock Limits Tips and Updates

UPDATED: AUGUST 2022

Update 08/30/2022: 🚨 Amazon Restock Limits Are Back for Q4 2022! Amazon has just imposed new restock limits on all sellers to ensure they can “receive, store, and fulfill products in a timely manner” this holiday season. The updated inventory restrictions will allow sellers to store at least four months of inventory in FBA. But expect to see a decrease in your restocking capacity if you already have a high utilization rate. If that’s the case, Inventory-Minded Marketing practices are more important than ever as making more space for your best sellers by getting rid of your aging, and excess inventory is necessary.

Read more ➜

Update 12/21/2021: Some good news on the Amazon restock limits and storage volume front. On December 21, 2021, Amazon made an important announcement regarding recent increases they made to Amazon storage limits for some sellers, with a promise for more increases in the new year. They have also lowered the IPI threshold from 450 to 400 which they say means that less than 10% of sellers will now have storage volume limits.

We always take this news with a grain of salt and, of course, Amazon did mention at their Amazon Accelerate event in October that they plan to eliminate restock limits altogether at some point. While we don’t see that ever happening (though we’d happily be proven wrong), this recent good news is welcome and we wait to see how impactful this update will truly be for sellers.

Shame that it, typically, came after the holiday sales rush, but it should be especially well-received among the sellers in the health, fitness and wellness space who tend to see a spike in sales after the new year due to New Year’s Resolutions. Read the entire announcement on Seller Central.

Update 11/24/2021: Amazon Restock Limits take into account “new selection” and adjusts appropriately. This means better restock limits for you catalog-wide when you create shipments for new to Amazon ASINs (added to catalog in the last 90 days). So you don’t need to worry about chewing up storage capacity when launching new products, and seemingly the more products you launch, the higher your limits will be. Amazon likely realized this was a blocker to the growth of their catalog and is adjusting accordingly. It is yet to be seen by how many units your limits will increase per added ASIN. Launching more products just got a little bit easier. Bonus Tip: If you are listing new Amazon products, consider taking advantage of the new FBA Selection Program to lower fees.

Update 11/08/2021: Amazon announced that additional FBA storage capacity for UK and EU sellers has now gone live. With this increase in FBA capacity, Amazon says sellers can expect to see an increase in their restock limits as well. More➜

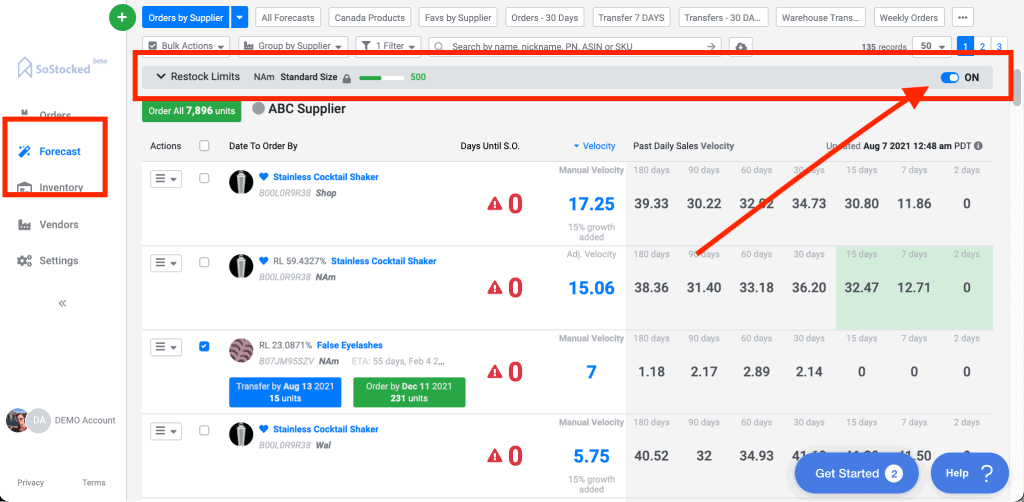

Update 08/06/2021: Factor Amazon Restock Limits into your inventory forecasts with the “Amazon Restock Limits By Storage Type” feature: See how it works➜

2021 Amazon Restock Limits Tips

Short on time? Watch my video below for my #1 tip for increasing your Amazon Restock Limits for 2021 before we get into the other Amazon Restock Limits updates and tips…

I hope you enjoyed my #1 tip in my video above for improving your Amazon storage limits. There’s so much more… so keep reading especially if your pulling your hair out with Amazon restock limits. 🤦♀️

Amazon storage limits create massive operational headaches.

Not only is it frustrating, it keeps on changing.

Amazon restock limits changed at least twice in 2020, again in 2021 and now Amazon promises more changes December 2021.

To make things worse, restock limitations are in their infancy and sellers have to weed through a lot of unknowns and glitches (more on that later).

To stay current, bookmark this post, or subscribe to get notified as I’ll continue to keep this article updated with announcements, quick wins, workarounds, and the new software features we code to make things easier.

Let’s dive in…

In this Amazon Restock Limits guide, we’ll take a look at:

- 2021 Amazon Restock Limits Tips

- How To Forecast Inventory Using SoStocked’s Amazon Restock Limits Tool

- 2021 Amazon Restock Limits Update

- Quick Wins To Improve Amazon Restock Limits

- Key Metrics To Improve Amazon Storage Limits

- Free Up Storage Space To Increase Restock Limits

- Optimize Logistics To Increase Amazon Storage Limits

- Adopt Inventory Best Practices To Improve Amazon Restock Limits

- Factor Amazon Restock Limits Into Forecasting

- Future Amazon Restock Limits Updates

How To Forecast Inventory Using SoStocked’s Amazon Restock Limits Tool

How It Works & How To Set It Up

Best Practices For Forecasting With Amazon Restock Limits

Common Pitfalls & Troubleshooting

What are Restock Limits?

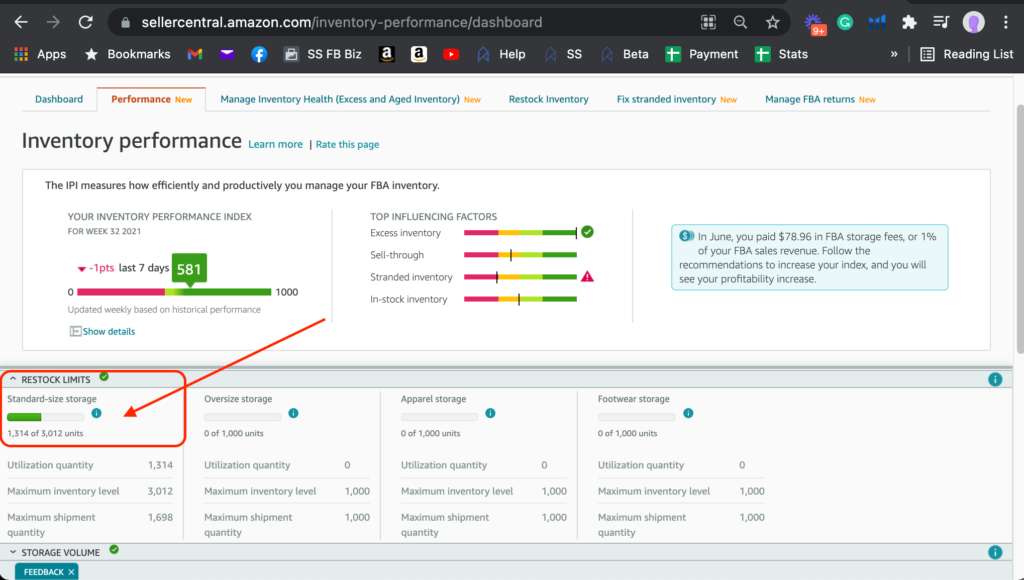

In April of 2021 Amazon changed its FBA storage restock limits from a product-level restock limit, to an account-wide restock limit. Amazon now limits the inventory you can store at their fulfillment centers, based on marketplace and storage type. For example, for the US marketplace, for Standard Size products, you will have one restock limit number. These restock limit numbers can be easily found by logging into Amazon Seller Central and going to this page: https://sellercentral.amazon.com/inventory-performance/dashboard

How to use the new tool

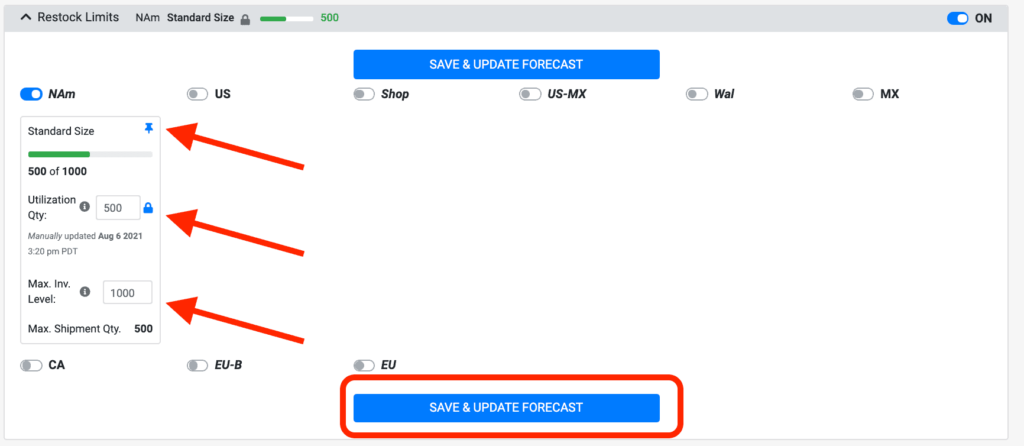

From your SoStocked Forecast page, turn on the tool by clicking the toggle button to “ON”.

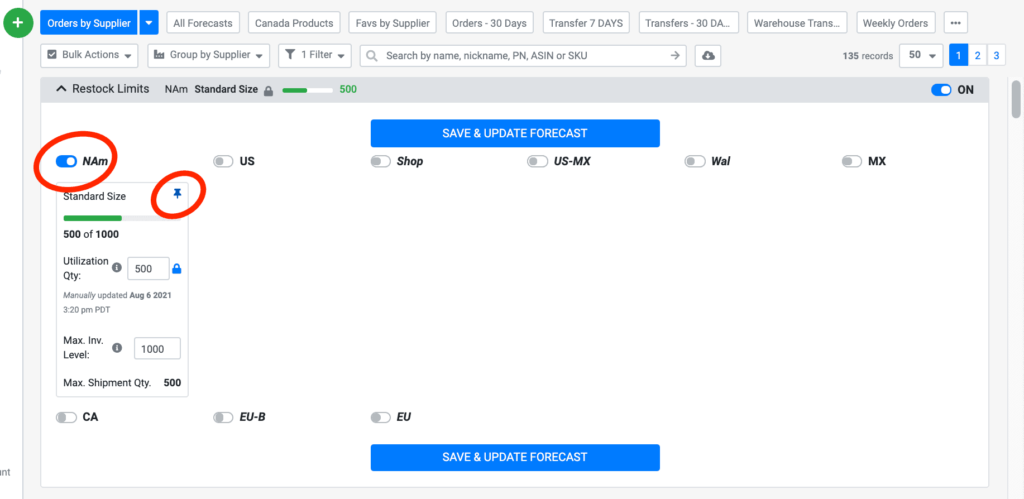

Now click on the gray bar to open the tool. From here you will need to update your marketplaces, by turning on or off the various marketplaces and storage types, depending on what you wish to track. For example, if you are only tracking NAM (North America) Standard Storage type, then turn everything else off. You can also pin your storage types to the top menu bar.

VERY IMPORTANT: Amazon does not provide us with an API data on Utilization Qty or Restock Limits. The restock limits number MUST be entered manually by you, for each storage type, for each marketplace.

The Utilization Qty is a combination of FBA shipments, sellable inventory, unsellable inventory and some other numbers. SoStocked will automatically enter this number based on adding up various data points from your API data reports. But if you log into your Seller Central and see a different Utilization Qty number, feel free to manually override our automatic figure by entering your own data.

NOTE: If you enter a number into the Utilization Qty field, a padlock icon will appear after you Save and Update. This means that SoStocked will not update this number automatically. So choose manual or automatic carefully.

YOU MUST CLICK SAVE & UPDATE FORECAST OR YOUR CHANGES WILL NOT SAVE.

How the Forecast Works

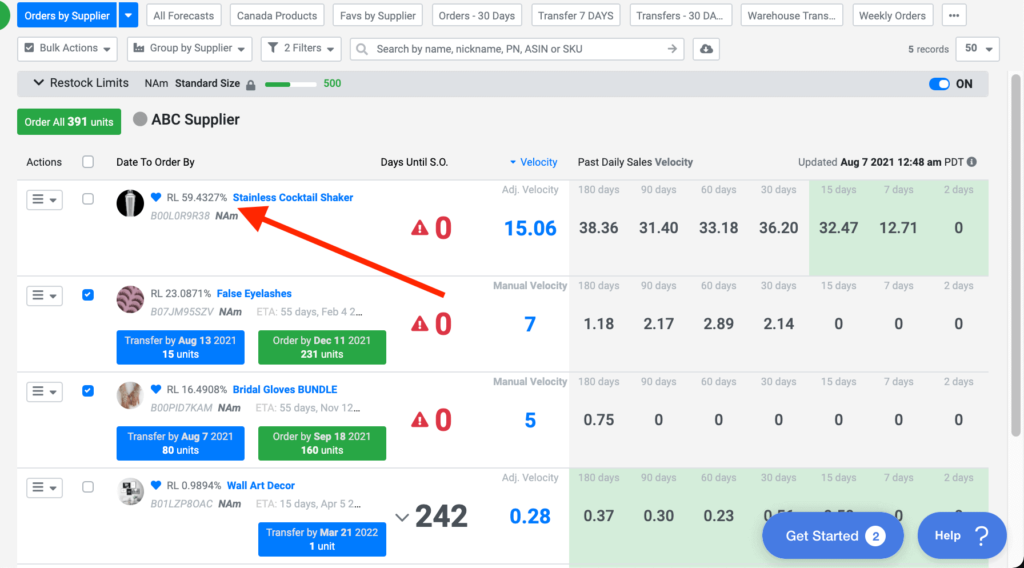

After you have saved your restock limits settings, the forecast will update. The new forecast calculation is based on a percentage of each product’s velocity compared to the TOTAL velocity for that marketplace. This number is represented by a % number displayed above each product.

For example, if you have 5 products in your NAM marketplace, and the highest velocity product shows 80%, that means that 80% of your NAM product sales are coming from that one product. This also means that SoStocked will allocate 80% of your total restock limits for that marketplace and storage type to that product. And so on.

Your green order suggestions and blue transfer suggestions will be based on your restock %, along with the rest of your standard forecast settings.

For more information on how the standard forecast settings work, study this article: https://help.sostocked.com/article/106-7-how-to-set-up-your-forecasts

How to Prioritize Products

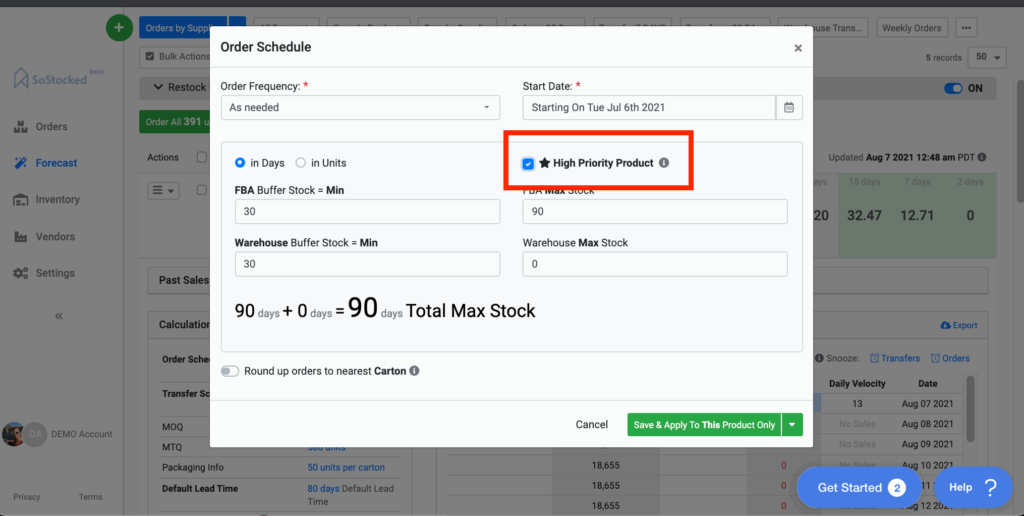

SoStocked offers a tool to manually prioritize a product’s restock limit forecast, regardless of its velocity %. To use the priority forecast tool, click into the product’s advanced forecasting tools by clicking on the product title, or the Days Until S.O.

From the Calculation Variables area, click the Order Schedule button. Now choose the High Priority Product box.

WARNING: ONLY USE THIS TOOL SPARINGLY, AS WE CAN ONLY ALLOCATE PRODUCTS’ RESTOCK LIMITS FOR A FEW PRODUCTS, OR THE CALCULATION WILL BECOME MEANINGLESS. WE RECOMMEND USING THIS TOOL FOR ONLY A FEW PRODUCTS. USE THE 80/20 RULE.

2021 Amazon Restock Limits Update

ASIN Limits Replaced With Storage-Type Limits

Back in July 2020, we discussed Amazon’s ASIN-level quantity limits for products that are stored in its fulfillment network. Amazon assured sellers that this change was to ensure that it could receive and store products for all sellers who use Fulfillment by Amazon (FBA), but it is safe to say that when this news reached the Amazon seller community, it was met with considerable backlash.

Now, in an attempt to rectify last summer’s actions, Amazon says they have listened to sellers’ feedback and have completely removed all ASIN-level quantity limits, replacing them with new storage-type level restock limits instead.

In the official news bulletin, Amazon announced:

“Effective April 22, 2021, FBA products will no longer be subject to ASIN-level quantity limits. Instead, restock limits will be set at the storage-type level, offering you more flexibility in managing your shipments.”

Basically, sellers’ restock limits are now at the account level, not the ASIN level, and they are measured by Storage Type. Each seller will need to check their own restock limits by first going to the Inventory Performance Dashboard in Seller Central, scrolling down to the bottom, and clicking on the Restock Limits tab. This will expand to show the Restock Limits on that account. Sellers can also review their total Storage Volume per Storage Type by clicking on the Storage Volume tab.

Good Or Bad News for Amazon Sellers?

The move comes after Amazon claims to have improved its policies and programs to better receive and store sellers’ products. So, this is excellent news for all Amazon sellers, right? 🤔 Well, on the surface, appearances can be deceiving. Some sellers have greeted the latest storage-type level restock limits with open arms; others have again found themselves in a debacle with this policy update.

It seems that while the new restrictions are favorable for some sellers, others are going to be struck by these restock limits.

While it is not clear yet if Amazon will address the issues faced by this recent update to the storage policy, solutions that we covered to alleviate storage issues last year, such as utilizing a 3PL warehouse, still stand as a viable option for the time being, though diving deeper into further solutions becomes necessary to mitigate the excess holding and handling costs involved in working with a 3PL. More Amazon storage limits solutions are discussed throughout this article.

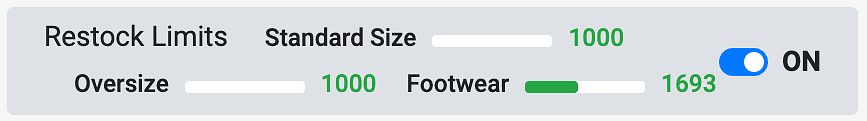

While it is still so new, what can be gleaned from the recent change is that, for new sellers, each storage type allows for 1000 total units of storage. The storage types consist of Standard, Oversize, Apparel, Footwear, and Aerosol (Restricted). For new sellers, it also seems that each category has a 200 cubic foot storage limit. In contrast, seasoned accounts that move higher volumes may have unlimited storage in theory, so long as your Inventory Performance Index Score is high enough, above 500 as of July 2021. Although with per-unit restock limits, it does not make for actual unlimited storage.

As far as immediate consequences, some sellers saw as much as a 40% drop in their storage capacity overnight as Amazon announced this change with no prior warning. Many sellers were thrown into being over the limit immediately. Some sellers even received emails letting them know that their already en route shipments had been canceled and they should contact their providers to have the shipment sent back. Some have taken the gamble, and Amazon accepted these shipments anyway, while others saw their shipments unfortunately, and expensively, rejected.

We cannot yet tell what Amazon’s formula is as sellers have reported everything from 2x, 3x, 4x monthly sales and beyond so nothing has been nailed down yet on that end. Further, we don’t know what will happen with seasonal product sales, anticipation stock, or Prime Day or Black Friday inventory and must all hold our breath and cross our fingers in wait. Another unfortunate unpredictability is the fact that Amazon has been known to drop limits overnight with no warning, making it even more difficult to predict and plan out FBA inventory allocations.

You can find more information about this new restock policy directly from Amazon by going to the Restock limits by storage type FAQ.

Quick Wins To Improve Amazon Restock Limits

Delete Unnecessary Inbound Shipments Immediately

Inbound shipments impact your utilization and potentially your sell-through rate. If your utilization looks high, you might have some shipments that you created a while back that are still open. Go ahead and delete those.

For example, if you have shipments that you aren’t currently using but are in the system, and Amazon thinks you’re going to be using them, delete those, especially if they are for products you’re not sending in. That will free up some of your space immediately. If you have an issue with deleting them, contact Amazon for help.

The sooner you delete those, the better because they likely factor into your sell-through rate, and that will carry through for the next 90 days as part of your average utilization. Read the Key Metrics section to see why this is by understanding what data Amazon uses to determine your sell-through rate.

An Amazon seller asked: “With Amazon’s new shipment creation flow, can I delete a shipment?”

I had this problem also; I had some shipments taking up some space, and when I tried to delete them, I got an error message. So we called Amazon and had them do it manually. If you can’t delete the shipment, call them up, and they will do it for you on their end.

Related: My Amazon Inventory Turnover article will help you to better understand utilization and how to calculate/automate sell-through.

Avoid the Amazon Double-Counted Inventory Glitch

An Amazon seller asked: “Why does Amazon limit me to sending in hundreds at a time when I’m selling thousands per day?”

This is an ironic conflict. If you’re selling thousands of units a day, you shouldn’t be restricted to only sending in hundreds of units.

Not everything Amazon does always makes sense, and lately it seems not much they do does. While I can’t claim to understand everything they do, I have discovered a recent error in the logic of Amazon’s restock algorithm that could prove to be the reason (and possibly the solution) for some sellers.

In late November, I changed one of my accounts over to the NARF program, the program in which you send all of your stock to the United States; Canada and Mexico are then fulfilled through your U.S. inventory.

I immediately noticed that although nothing happened to the lower velocity SKUs, some of the higher velocity SKUs lost their restock limit.

Now they didn’t actually lose the limit, but I couldn’t see it in the reporting. I didn’t know what the limit was because it wasn’t showing anymore. Where it had been there before NARF, afterwards it wasn’t pulling into SoStocked so I checked Seller Central and when I exported my report, I couldn’t see it there either.

I noticed immediately that the NARF program had a glitchy effect on my restock, and a few days later, I discovered that the inventory for NARF products, especially higher velocity SKUs, was sometimes getting double-counted by Amazon’s restock algorithm. It was counting for the US and then the same inventory again for Canada. I noticed this in some of our users’ accounts as well when I was assisting them in SoStocked.

For example, you may have 3,000 units in inventory, and can clearly see 3,000 in the U.S. and the same 3,000 available for sale in Canada. Understand, it is the same 3,000, yet Amazon would be double-counting the inventory, which would affect your Max Ship Quantity – the remaining amount of inventory you’re allowed to send in. Max ship quantity is restock limit minus current and inbound inventory. So, if you have 3,000 using NARF, for some SKUs, your inventory could say 6,000, effectively eating away at your Max Ship Quantity and potentially blocking you from sending in new shipments.

My theory is that the NARF program is doubling these numbers. As we looked further into one seller’s account, his inventory showed 3,000 with a limit of 5,000. The amount that showed against his restock limits was 6,000. Although the numbers were showing 6,000, he really only had 3,000. The program was double-counting his higher velocity inventory. He should have been able to send in 2,000 units and instead Amazon said he was over the limit by 1,000 units.

The bottom line is that your inventory may be double-counted if you’re using the NARF program, which means you’ll have difficulty keeping inventory in stock.

If you are experiencing this, my suggestions would be to:

- Try unenrolling in the NARF program to see if that corrects it for you.

- Meanwhile, document it and send it to Amazon.

- Escalate your email to the executive team: [email protected].

- Address the issue in the subject line.

I don’t recommend emailing Amazon’s exec team about every little thing. Still, they are responsible for broken systems, so if you can delineate what’s broken and show them how, the system itself will usually get handled more quickly than if you go through the regular channels where, quite often, it’s just batted around and ends up leading nowhere. The more we let them know about this, the more likely they’ll address this issue.

To summarize:

- Check your levels for double-counting

- Document it

- Report it to Amazon

- Turn off the NARF program to see if that will fix the problem. If it does fix it, it might be more beneficial to stay in stock in the U.S. than to grab the handful of sales that you might get in Canada by having the NARF program enacted. This might reset your limits and handle the glitch if it’s a conflict of these two different algorithms inside Amazon.

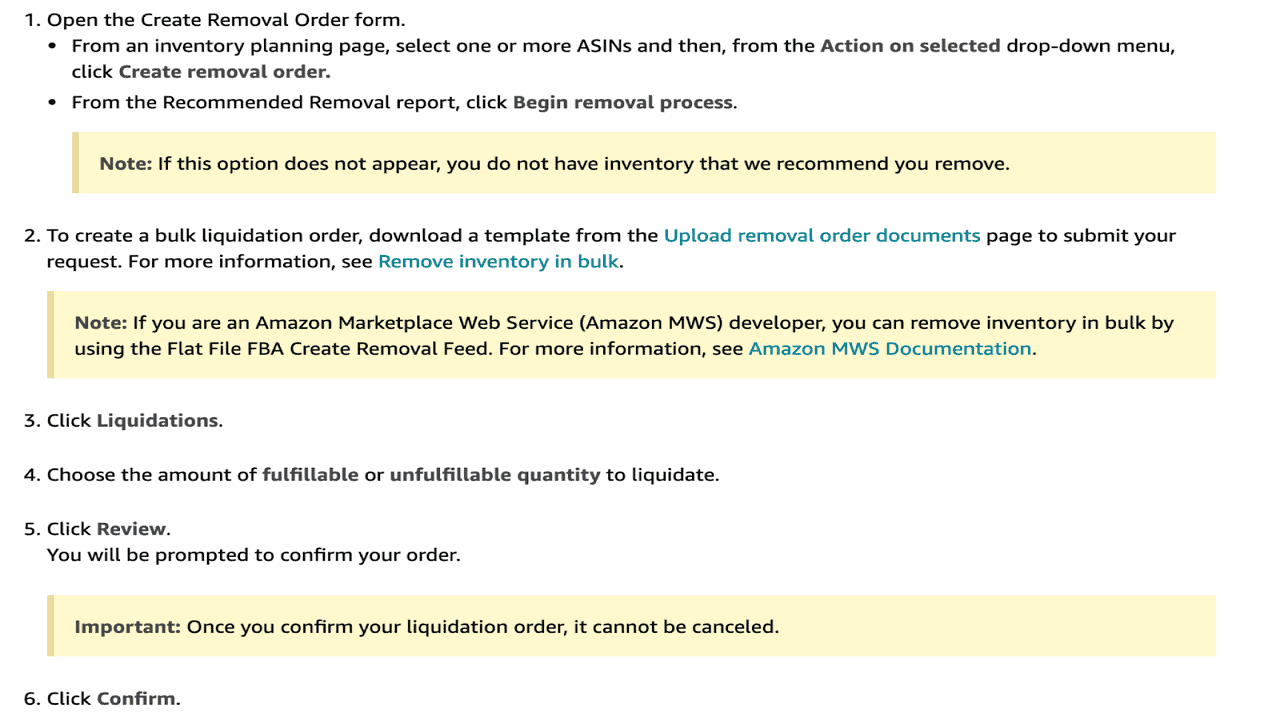

Use Amazon’s New FBA Liquidations Program

Amazon now has a program within FBA for liquidation, which means they’re assisting sellers in recovering some profit while clearing out stale inventory.

Amazon says that you’ll recover 5-10% of your item’s average selling price, and will be paid about 60 to 90 days after the liquidation order is submitted. It’s not going to be a considerable amount of money, but it’ll be something as opposed to nothing! It can sometimes be a better option to clear out that inventory than to stock out on a best-selling product because you couldn’t get the storage space to move it in on time.

You might want to consider this option if you have a dud product and don’t expect to make much money from it, you just want to sell through it, or it costs you a lot in Amazon FBA storage fees because you’ve been carrying it for over a year.

Here’s how to increase Amazon FBA storage space with the new liquidations program:

As you can see here, you’re going to create a “Removal Order” as you usually do and then choose the “Liquidation” section. And if you want to liquidate products in bulk, you can download a Flat File to do a “Bulk Liquidation Order.”

Unfortunately, liquidation fees apply if your inventory is shipped to a liquidator. Amazon will be charging you a certain amount per unit based on the product’s weight.

Here is a glimpse at the fee schedule:

When you send these Amazon removal orders directly to a liquidator that Amazon has an agreement with, you have to pay these fees.

Make sure you do the math to determine what you could make back after figuring out what Amazon will charge you based on their fees.

Pros and Cons of Amazon FBA Liquidations Program…

Pros

- Free up space. The apparent pro with this new liquidation opportunity is that you’re freeing up space. You can allocate that available space to your best-sellers or new products.

- Additional money. You can make a little extra money by selling your slow sellers or excess inventory at a discounted price, which is better than disposing of them.

Cons

- Amazon removal orders don’t count towards sales velocity. If you want to move excess inventory to clear out space and ramp up your monthly velocity at the same time, which can potentially increase your Amazon restock limits, it might be a good idea to rethink using liquidation as your go-to option. I recommend running a flash sale or trying to sell them using multi-channel fulfillment instead. If you choose to do a multi-channel fulfillment order, that will also count towards your sales velocity in Amazon and could boost your storage limits.

In sum, if you’re trying to decide between a fulfillment order or a removal order, Amazon will generally tag a fulfillment order towards sales velocity and a removal order will not contribute towards that velocity. Liquidation, to this point, is a form of removal order and will not help to boost your velocity or increase limits, but will merely clear space within the limits you already have.

Related: How to create an Amazon Liquidation Dashboard and an Amazon Slow-Sellers Dashboard.

Get Inventory Delivered & Checked-In Faster

An Amazon seller asked: “How do I get an earlier appointment to deliver to Amazon FBA and get things checked in faster?”

Here’s a tip you can try! I did a webinar with Randy Thebeau, owner of Viable Shipping. He’s an Amazon seller, as well as a warehouse owner. You can find the webinar on YouTube entitled, “How to Avoid Getting Screwed by Warehouses and Fulfillment Centers.

In our discussion, Randy talks about using UPS Freight, because the rates are good and because they have a standing agreement with Amazon, which allows them to truck shipments in whenever there’s a gap in the schedule. Amazon never wants a dock not to be unloading or loading in stock.

When there is a gap, Amazon will call UPS and ask them to send whatever they have. Because of the agreement between UPS Freight (not regular UPS) and Amazon, shipping into Amazon tends to be much faster using UPS Freight.

Key Metrics To Improve Amazon Storage Limits

Understand Sell-Through Calculations

Sell-through is a crucial metric of Amazon. From what I can gather, it is the most important inventory metric for Amazon. See, Amazon never intended to be a storage facility. They have always and only wanted to be a distribution center. What this means is that they do not want to keep your stuff parked and collecting dust in their warehouses.

This is why sell-through is so important to Amazon. All of their inventory actions and recent policy changes point to sell-through as the vital statistic we should all be focusing on. In fact, if you understand how Amazon calculates sell-through, you can also recognize that all four of the metrics that make up your IPI Score factor in part or in whole into your sell-through rate.

Amazon will tell you that sell-through has a lot to do with restock limits. Of course, other factors surrounding restock limits are calculated into the algorithm, including future sales for seasonal products and Prime Day Deals (if you have a Prime Day Deal scheduled), plus other things that only Amazon algo builders and senior execs can know, apparently. Still, sell-through is one of the major ones. Again, Amazon doesn’t want to continue to store the stuff that’s not moving, so they’re penalizing sellers with dud products that are just squatting in their warehouses.

Let’s take a look at exactly how they calculate sell-through.

Amazon’s definition for calculating sell-through is:

Sell-Thru Formula

Units sold or shipped within 90 days / Average units available = Sell-Through

“Your FBA rolling 90-day sell-through rate is the number of units sold and shipped over the past 90 days, divided by the average number of units available at fulfillment centers during that time.”

Traditionally, 30 days has been the number we’d most associate with sell-through, as in monthly sell-through. However, Amazon is laying out it’s parameters as 90 days, which means that what you’ve done over the past three months affects your sell-through rate,extending the timeline to getting your past missteps off of your track record. And what you do now will have ramifications for the next 90 days and stay on that record.

Let’s take a deeper look into the reality of Amazon’s definition of sell-through. Again, the formula is units sold or shipped within 90 days, divided by the average units available.

For example, if you sold 9,000 units within 90 days, and on average, you keep 3,000 units, then your score or sell-through rate would be three. You would be turning over your inventory every month because 90 days divided by those three months would be 3,000 units. And then, if you sold the same 9,000 units but kept 9,000 units in stock, you would have a sell-through rate of one, which would be a quarterly turnover.

Monthly Turnover Example

9000 units/3000 units = 3

Quarterly Turnover Example

9000 units/9000 units = 1

Amazon would prefer if you would turn your inventory over monthly rather than quarterly or longer.

They don’t want you to send a bunch of inventory directly to FBA for months on end anymore. They’re forcing all of us, as professional sellers, to keep inventory at external warehouses. If you’re still only using FBA, you want to rethink that, whether it’s finding a local warehouse or asking your warehouse in China if they are willing to hold your inventory for a prolonged period. You’re going to have to change the infrastructure of your logistics. More on that later.

Related: How to create a 3PL Logistics Backup For Amazon

Understand Importance Of Utilization

Restock limits are like credit scores. Amazon doesn’t want to give you more storage if you’re not correctly utilizing the storage you already have. For example, if you have a higher-than-quarterly turnover and haven’t proven that you’re able to turn over the products you’ve sent in, they’re not going to want to give you more storage. Inventory-wise, Amazon judges you based on your ability to turn over products. It’s kind of like a debt-to-credit ratio, in the same way that a creditor is not going to give you more credit when you have a lot of debt. They’ll give you more credit when they see that you’re good with credit.

Utilization can also directly impact sell-through because it factors in the average number of available units. If you would like to know your utilization percentage, take your FBA available inventory + reserved inventory + open shipments divided by your restock limit and multiplied by 100 and you will have your utilization percentage. To find these numbers, go to your “Inventory Dashboard” then to the “Inventory Performance” tab and scroll down to click on your “Restock Limit” and find your “Utilization Quantity” and “Restock Limit,” known in Seller Central as “Maximum Inventory Level.”

For example, if you have 3,000 units combined as your Utilization Quantity and divide it by your Restock Limit of 10,000, you would have 30% utilization. Thirty percent utilization is also like a sell-through of about three, and your turnover would be close to monthly at that point. Similarly, if you have 9,000 units and your restock limit is 10,000, that would be a 90% utilization, and your turnover would be quarterly.

Utilization Example 1

3,000 / 10,000 = 30%

Utilization Example 2

9,000 / 10,000 = 90%

If you are at the edge of your limit and maxed out, you might want to look at what you have been selling. If you’ve stocked out, Amazon will not give you the benefit of the doubt by factoring that into your limits. If you miss out on 1,000 units in sales due to the stock out, it’s more than likely that your restock limits in the future will decrease because of this.

This will also hurt you because your sell-through will be injured from that stockout for the next 90 days. You’re also going to have trouble with the restock limits if you have seasonal products and Amazon’s algorithm is not picking up on your season coming up.

An Amazon seller asked: “Would you suggest immediately utilizing free space once your limits improve?”

This is a great question. You’re going to affect your utilization and sell-through rate, which will make your score even worse. One of the significant markers that Amazon uses to decide whether or not you should have those limits is if your scores are decreasing. Your score falls when you’re sending too much inventory in, and that counteracts how Amazon wants us to operate.

The other thing to factor is whether you should be taking advantage of the current limits just in case Amazon decides to take them away.

Amazon did lower the limits right before Prime Day in 2021. If your big sales season is coming up, you’re launching new products, or you have an upcoming promotional sale, you might send that inventory in, but I wouldn’t make it a regular practice.

To summarize, don’t send in three/four months’ worth of inventory just because Amazon’s letting you; it will work against your utilization and sell-through. They’re trying to award people that have good utilization and good sell-through. Having inventory there just to have it and because you don’t want to or can’t move it isn’t going to benefit your account.

Free Up Storage Space To Increase Restock Limits

Identify Slow-Moving Products With Excess Inventory

Due to the new Restock Limits by Storage-Type, the fastest way to potentially increase restock limits is:

- Identify slow-moving products with Excess Inventory.

- Rapidly sell through that inventory BY ANY MEANS NECESSARY.

RESULT: Not only do you clear slow-sellers that are blocking your best-sellers, but the added sales velocity helps to increase your overall restock limits.

HOW-TO: Use the SoStocked.com Sales Velocity and Days Left on AMZ filters to quickly identify overstocked slow-movers.

Now is the time to start looking at any of your excess inventory. If you haven’t already done it, get rid of slow sellers to free up storage space and improve those metrics. Consider removing anything that’s more than 60 days. We used to recommend 90 days, but since Amazon’s policy change, 60 days is probably safer. You should start keeping more inventory in your local warehouse and less at Amazon.

We have to be prepared for a margin crunch because Amazon is forcing us to take on more expenses. There will be more carton fees because there will be more cartons that we’re not sending directly into Amazon so our third party warehouses are handling them. We’re also potentially looking at more storage fees. It’s time to get smart about how we’re handling things. Removal orders will get the job done quickly but will also cost you.Using a removal order, you can move some of that excess inventory out of FBA warehouses.

A flash sale would be a little slower, but could have some potential upsides in addition to what a removal order would do for you. First of all, it should cost you less; it should be more profitable for you to move it through a flash sale. Second, even though it might take longer (or might not be possible depending on the product), it’s not only going to clear up space, but it’s also going to improve your sell-through rate because Amazon is looking at your total sales and total inventory balance. And that could potentially mean improved restock limits shortly.

As mentioned above, you can also check out Amazon’s new liquidation program: essentially, you can create a removal order, and Amazon will charge you a per unit fee. They’ll send it to a liquidator, and then the liquidator will pay you 5-10% of the value of those units within 60 to 90 days.

Related: Why Amazon Excess Inventory is bad and how to reduce it.

Lower FBA Buffer Stocks

I don’t mean you should lower all of your buffer stock, just your FBA buffer stock – potentially and with caution. We recommend 30 days of FBA buffer stock, but so for those keeping more than than, 45 to 60 days, rethinking that may be in order. Buffer stock is that extra bit of inventory that you always keep; it’s like a false zero.

Before I get down to 30 days, I’m shipping in with enough time for my inventory to arrive before I hit 30 days of stock. However, this is a balancing act. In recent updates, we mentioned that Amazon claims they are trying to improve on check-in times. Thirty days of buffer stock will not do you any good if they’re taking three weeks to book an LTL appointment and another three weeks to check inventory in, so don’t automatically shift to 30 days. I would say slowly creep it down as you start to trust those check-in times. You don’t want to stockout. As those check-in times get faster and faster (fingers crossed), start to creep your buffer stock down while creeping your warehouse buffer stock up to make up for that shift in balance.

And, of course, always have a backup plan. Unfortunately, because Amazon is taking weeks to check in inbound shipments, products stock out while waiting for this check in, and your sales decrease. Because of this, your sell-through decreases, your restock limit goes down, and the sales that would give you the ability to send more inventory decrease while your likelihood of stocking out increases.

Related: The importance and difference between Buffer Stock, Safety Stock and Anticipation Inventory.

Optimize Logistics To Increase Amazon Storage Limits

Smaller Shipments More Frequently

I know we don’t like to hear this one because it could cost more money to make smaller shipments more frequently. But instead of shipping three or four months’ worth of inventory into Amazon, we’re more likely going to have to do it once or twice a month; at the very most, I would say every two months because, in part, more frequent, but smaller shipments will increase your sell-through. And that’s what Amazon wants to see.

They want to see that you’re good at turning your inventory over, and this should trigger Amazon to want to give you more space. It’s ironic: we’re all trying to get higher restock limits, and at the same time, we have to start thinking about keeping our utilization down so we’re not maxing out those limits. Max out your limits, doesn’t seem to be an effective trigger to Amazon to increase those limits, unfortunately.

The benefit of getting your utilization down, getting those restock limits up, and not using all of that space is that you will have the extra space if you do want to launch more products and are trying to scale more quickly.

Additionally, if you’re sending smaller shipments, not palletizing them will potentially help you get them checked faster because it takes less time and is processed a little differently.

Pro tip: If you decide to go with smaller/frequent shipments, consider using SoStocked to remove complexity & gain visibility by keeping track of where inventory is in the process (production, customs, prep center, 3PL, in transit etc…).

Faster FBA Shipping Times

We used to label everything with FBA shipping labels and put it on a slow boat from China. I’m not saying you can’t do ocean freight, but it may not be the best move to label your FBA shipments before you put them on the boat. As soon as you create an FBA shipment that will keep for 30 to 45 days, it’s going to eat up your utilization space, and it’s also going to affect your sell-through – you’ve got potentially thousands of units that are not selling for 45 days. Even worse, ocean inventory may take up the FBA warehouse space that is needed to send local inventory into Amazon. So put them on the boat and then label them when they get to your third-party warehouse.

On top of all this, Amazon checks your sell-through algorithm and may attribute those products as part of your FBA inventory as one factor of their sell-through calculation. Unfortunately, the algorithms can be a little faulty, and thus creating these labels could be harmful to utilization and sell-through.

This is why we recommend that you consider sending your inventory to a third-party warehouse and labeling them to FBA from there. This means extra fees because you have check-in fees at your third-party warehouse as well as labeling fees and shipping fees. As prices are beginning to come down on air freight, it seems that it might start making more sense to send smaller portions by air for smaller products.

Sometimes your Chinese warehouse will let you store things there for free, and then you can send in batches to Amazon if that makes sense for you financially. Run the numbers and see how much it will cost you to store them at your third-party warehouse locally, along with all of those extra carton fees, labeling fees and handling fees, compared to how much air freight will cost you. Never assume that air freight is always the most expensive option now that you have to do this pit stop to your third-party warehouse because of Amazon storage limit restrictions.

Pro tip: To save on some of these warehousing fees, consider increasing the number of units per carton. This will immediately have an impact on your carton fees. You’ll have fewer cartons because you have more units per carton, and each fee will be more evenly distributed across all units for increased per unit profit. We did this on one moderately selling product; we did the math on adjusting from eight units per carton to just 10 units per carton, and it was an $8,000 per year savings! Ask your supplier if it is possible to safely pack your inventory differently to have more units per carton. You may even want your inspection company to check the stability of the change to ensure safe travels before you wholly switch over, but that change should be a quick way to regain some margin.

Lower Shipping Costs Caused By Amazon Restock Limits

An Amazon seller asked: “Restock limits cause me to ship products via air ($15 per unit) instead of boat ($1 per unit). Doesn’t it account for overseas shipment transit times?”

This is so challenging! It’s true, as we discussed above, that if you are shipping inventory into Amazon, the minute that you say you’re shipping it, it will be counted as inventory. It’s not going to look at when the inventory is going to arrive but is going to count it immediately.

If you make a Chinese shipment, you may be blocking your local warehouse inventory from getting in. In this case, it would make more sense to have a 3PL. If you’re paying an extra $14 per unit by air, sending by sea and then having a 3PL store and ship for you will be significantly less expensive.

By sending all of your inventory to your 3PL, and then paying a carton pull fee along with a labeling fee, you’ll be paying those per carton and per pallet fees rather than the high air freight, which should reduce your cost per unit significantly. And even with those extra costs, I can’t imagine (unless you’ve just got some crazy products) it costing you as much as $14 extra per unit to switch to ocean freight and 3PL rather than air shipments.

This way, you won’t have to create the FBA shipments until your inventory arrives at your 3PL, and then you won’t have to do the air freight because you’re not initiating that shipment until they’re only days out from arriving at Amazon from your local warehouse.

Keep Storage Space Limits In Mind

An Amazon seller asked: “My product sales increased last month and I kept max inventory in stock. Why did Amazon lower my restock limit instead of increasing it?”

Generally speaking, if your sales are increasing, you should not have a limit lowered. In this case, some sales may have been rolled off because of your past sales timeline. Amazon tends to look at your sales velocity for the past 30 to 90 days and adjust your restock limits accordingly. It may also factor in future sales patterns based on last year’s sales which could be why some sellers are seeing strange numbers. (It is my belief that Amazon’s current restock algorithm is in its infancy and with next to no feedback from actual sellers – a recipe for disaster as we have seen.)

To illustrate, I will use last year’s Prime Day as an example: Prime Day was on October 13th, 2020. It’s possible that, given this shift in restock limits, the sales from Prime Day simply rolled off, and this shifted the 90-day sales, and sell-through and restock limits were possibly lowered for that reason. It could also be that Amazon is fortunately or unfortunately, factoring in what your sales patterns were from last year.

Another factor that none take any comfort in is that Amazon has decided, at times, just to drop limits at its own discretion. Sometimes platform-wide and sometimes picking and choosing by category or even by metrics unknown to us at this time. They did this in mid-May right before Prime Day 2021 with no prior warning and just a brief email explanation sent out after the fact. It’s likely they will do this again and it’s out of our control, unfortunately.

As another possibility, you could also look at the NARF issue that we discussed earlier in this article to see if the stock is being double-counted, affecting the amount of inventory you’re allowed to send in.

You would additionally want to check space volume limits on your account. Many accounts with lower IPI scores will have a certain amount of space limits. Many accounts actually have unlimited space limits. It just depends on your IPI score and what is happening with your specific account.

If you do have a space limit, you may want to look into seeing if you have overstocked products that are taking up too much room, which means you can’t get your better-selling products in there. Check to see if you can free up some space by removing that inventory. Those selling oversized products will tend to have this problem even more often because these can tend to take up a lot of space with much fewer units and use up your storage volume a lot faster.

However, it is going to cost you to remove inventory. At the time of this writing, each unit is going to cost you between $.25 – $1.90+ depending on size, and disposal, which used to be much cheaper than removal, will now at the time of this writing, actually cost you the exact same in fees.

So when do you actually decide to incur that cost and remove or dispose? If it’s something that you really want to liquidate and get rid of, if space limitations are hurting your inventory strategy, it might make sense to free up that space so that you can continue to prioritize your top sellers. So keep that space in mind because for some sellers it’s not just your per unit limitations; it’s actually space limitations. You want to make sure that you have enough space to keep your top sellers in stock.

Here’s how to check for your space limitations.

- Go into your Amazon “Inventory Dashboard.”

- Next, go to “Inventory Performance.”

- Scroll down to the bottom. You’ll see an arrow that says “Storage Volume” click on it.

- It will open up the panel on the bottom and give you the storage volume limits per storage type: Standard-size, Oversize, Apparel, Footwear, and, where applicable, Flammable and Aerosol.

Another reason to remove or dispose would be if you calculated the removal cost against storage cost and the likelihood of actually selling the product on Amazon and decided it would cost more to keep it than it would to kill it.

Pro tip: Around August or September, Amazon often offers free removal or disposal in preparation for the holidays. It would make sense during that time to take advantage and pull any items for free that you don’t think will sell and that you want to liquidate. This should potentially be part of your annual inventory strategy. Note: Amazon usually won’t let you restock the SKUs you pulled using free removal for the next 6 months or so, so be sure you really do want to pull that stock and not send anything more into FBA for that period of time.

Beware Of Seller Stockout Cycles

An Amazon seller asked: “If I run out of stock and want to maintain my restock limits, do I need to switch to FBM (Fulfillment by Merchant)?”

The short answer is less, but there are a few more solutions that we will provide that aren’t necessarily being talked about too much right now. Let’s explore.

Alright, to start, let’s say your limit is 5,000. You stockout and slowly go down to a 4,000 unit limit. This creates a stockout cycle since you aren’t allowed to send enough inventory this next time around. You stockout again at the lower limit, this time for longer. Consequently, you have a yet lower restock limit. Of course, check-in times have been longer than expected, making matters worse. This is a dwindling cycle because the more you stockout, the lower your restock limits are.

So here are some questions we want to ask and answer:

- If you switch to FBM, are you going to retain those restock limits?

- If you stockout at FBA (Fulfillment by Amazon), but you’re continuing to make sales and sell at a slightly slower rate because you’re not selling Prime, is using FBM going to contribute to maintaining a restock limit?

And the answer to both is YES! Sellers have seen their limits maintained when using FBM. They were able to hold onto that limit or even increase it if their sales increased at that point.

Even if margins are significantly lower with FBM, and shipping is often more expensive, cutting into your margins, it still might make more sense to use FBM. Why? Because you’re not going to get into that awful, dwindling stockout cycle since you will be maintaining the restock limit.

Above all, don’t stock out. If you do, you should be switching to FBM if you can.

If you do stockout at Amazon, you should have a backup to switch to so that you can still fulfill orders. You need another outside fulfillment center. Don’t ever send all your inventory to Amazon! You still need to deliver to your customers even if they don’t check in your inventory. They should not be your only distribution channel, even if they are your only sales channel and you’re not selling through any other platform.

Switching to FBM is essential, the reason being that if you stockout at FBA, the FBM sales will still contribute to your restock limits. Your sales may be lowered just a little because you didn’t have Prime, but you will still maintain instead of stocking out, which hurts and drops that limit.

The other two methods to utilize are:

- Borrowing sales velocity from an overstocked product by doing a flash sale to move inventory on products with excess inventory while you are stocked out on your top product. That will help to boost overall sales velocity so that you can maintain while out of stock on other products.

- Borrow sales velocity from other channels using MCF (Multi-Channel Fulfillment) such as having Amazon fulfill your Shopify sales. The Shopify velocity will add to your Amazon velocity when they are doing the fulfilling so making this temporary switch will also help to up the velocity and maintain the restock limits.

Related: What Is A Stockout And 9 Ways To Avoid It

Adopt Inventory Best Practices To Improve Amazon Restock Limits

Use Daily Adjusted Velocity

You don’t want to forecast demand based on the total number of sales because you’ll be factoring any stock outs into your calculation. Instead you want to do it based on daily adjusted velocity.

If I’m looking at 30 days worth of sales and was stocked out for 10 of those 30 days, I only want to look at the 20 days that I had inventory in stock. That’s what the SoStocked Amazon inventory management software does for you. Regardless of the system you’re using, you should look at your average sales filtering out anomalies like stockouts and sales spikes. This helps to determine what your most likely future velocity will be without muddying your data with stockouts or making huge sales spikes due to a one-time promotion that won’t repeat itself, such as being featured on a morning news show.

See, if non-recurring sales spikes get calculated into your equation, it might cause you to purchase more inventory than necessary.

You also need to be aware of whether you’re looking at last year’s sales. This one can get you into trouble as it’s harder data to keep in your head. You might remember stockouts that happened 30 days ago but you might not remember exactly what happened a year ago. So when you’re doing your Christmas calculations, you need to also factor in your stockouts and spikes during that time. If you stocked out, you want to remove that from your calculation and instead average out what you would have sold if you hadn’t stocked out.

Related: Watch the Adjusted Velocity SoStocked.com demo

Take An Inventory-Minded Approach

We developed the concept of inventory-minded marketing because marketing teams can no longer only be focused on marketing in a vacuum. They have to involve the inventory team in the marketing process to avoid stocking out and, nowadays, to know which products they need to push on to move out of FBA storage facilities. Only by Marketing and Inventory working together will your inventory system become more stabilized, more efficient, and more profitable.

Marketers have to become responsible for understanding inventory and for marketing across the entire catalog. It used to be that marketers could focus on the best sellers, and it was okay to ignore products that didn’t do well. When they sell out, they sell out. But that’s not the game anymore. Marketers have to market all products aggressively and can’t forget about these slow sellers.

It’s a double-edged task now. They have to market hard enough to drive revenue and sell-through but not so hard and fast (and uncoordinated with Inventory) that you run out of inventory. I like to say that a good marketing plan turns bad fast when it’s so successful that it stocks you out. A stockout like that will heavily impact your business. There are specific coordination points that have to be in place between the marketing team and the inventory team.

Download the free Amazon Marketing Plan Template that we have built to help the marketing team and the inventory team coordinate. It will help you to organize a plan for the marketing team to keep the inventory team informed.

You can also learn more about how we structure an inventory-minded marketing program in our webinar “The Inventory Planning Work Party.” It will allow you to visualize how the entire system works together and utilize a “slow-moving products” report and the “liquidation” reports.

Lastly, consider using specific reports to stay on top of your inventory, including:

- Stockout Risk Reports

- Slow-Sellers Reports

- Liquidation Reports

- Overstock Reports

Use Min-Max Restocking

Min-max restocking is a method for setting parameters to make sure you, theoretically, never stockout or overstock. For example, if 30 days is my minimum, I want to keep at least 30 days worth of inventory in stock at all times. I never want to go below 30 days worth of inventory, and I never want to go above 90 days. This strategy helps to automate your orders by calculating the perfect reorder point and quantities, and it’s going to help you pass this task off to your VA so that your VAs know how much and when to send in more inventory. It’s beneficial when you know this new storage type has a lot to do with avoiding stockouts and overstocking.

Start by opening up your Transfer Schedule in the Forecast section of SoStocked. I recommend setting your Min-Max “in Days” because it will fluctuate based on your sales from season to season and as your velocity changes. Set your preferences to never go below 30 days or above 60 or 90 days worth of inventory max. The software will let you know when you get close to that 30 days and tell you to ship inventory so that by the time it’s arriving, you’re hitting that 30 days. Then it’s going to tell you to stock up to your maximum, which is 60 or 90 days, or whatever setting you selected. You’ll then sell through to your minimum, then the software will tell you to re-stock back up to your maximum, etc. Min-Max Restocking is all about automating a good turnover; it provides you with a sound system for knowing what to send and when.

You also need to put sales promotions into that calculation. Let’s say it’s Prime Day, and you’re going to sell 500 units. The 500 units will be added into that calculation so that you’re sending in precisely what is needed at the time that it is needed.

With Amazon’s restock recommendations, it doesn’t predict your future sales events and help you to factor that into your restocking. That’s another story in itself; which is why we’ve built the Inventory Timeline and Min-Max Restocking to work together. Once the marketing team sends all of this information to the inventory team, inventory can plug this information in and get a great visual of through this Timeline, showing them the inventory depletion as time goes on and when shipments are arriving.

Related: Watch the Min/Max Restocking and Inventory Timeline SoStocked.com demos.

Get Good At Simultaneous Forecasting

Simultaneous forecasting is merely the reality that you are usually not doing one but two and sometimes three separate forecasts for each SKU at all times. You are calculating a reorder forecast for when to produce more inventory at your factory, another to determine when to transfer inventory from your local warehouse into Amazon and possibly a third to predict any express/air shipping that needs to be done to prevent a potential stock out.

Especially in Amazon’s new restricted inventory world, simultaneous forecasting is something that you’re going to have to become good at. You need to be watching everything at all times and to know what you have where and when it will arrive.

You need to have calculations for how long it takes for your shipments to arrive at each point in the process. For each product, supplier and warehouse, you need to know:

- How long does it take for my orders be produced

- How long are shipping times from supplier to warehouse or FBA?

- How long does it take to transfer inventory from my 3PL into Amazon?

- How long does it take if I have products being held at my Chinese warehouse?

- How quickly can I get an express order sent in?

- And most importantly, what are my worst case scenarios and how do I recover from them?

You want to be as flexible as possible and at the same time figure out how to mitigate costs wherever you can. You want to keep inventory at your local warehouse, but you’ll also likely want to keep a good deal of stock with your Chinese supplier in their warehouse where they’ll often not charge you. To reduce some of your storage and handling expenses, consider a new arrangement where your supplier holds some of your inventory for a few months at a time. Sometimes you can arrange to pay your 30% deposit and then pay the other 70% in batches on only the inventory you ship out when or after you ship it. This way, you’re keeping some of that cash flow a little more fluid while they’re holding this inventory.

Factor Amazon Restock Limits Into Forecasting

You probably know that SoStocked was one of the only (if not the only) software to accommodate Amazon restock limits if you were around during the July 2020 IPI limit threshold change. SoStocked’s per ASIN per marketplace calculations hugely helped sellers during that frustrating time.

Given the new 2021 Amazon restock limits, we are working to implement forecast calculation changes across the entire platform to account for this new change. What it would consist of would essentially be to plot out and allocate a certain percentage of inventory storage space per product, categorizing your entire catalog in priority order to ensure you never run out of your best sellers.

Our team is working on this now and very close to completion. We are in direct communication with the Amazon API team to get the much-needed restock limits by storage-typeinformation to make this happen in an automated way. While much of the information is still not yet available via Amazon’s API, we are working on workarounds until it can be fully automated. These workarounds will still save sellers much of the calculation and allocation time and better help them to plan for success and scaling.

All in all, this is another Amazon sucker punch that makes things worse while claiming to make things better, but as we dive deeper into the nuances of the Amazon storage-type algorithm we are recognizing new flexibility and ingenuity that can be developed by way of clever logistics shifts and inventory and marketing strategies which were not previously available to us with the former ASIN-type limits. So all is not dark and dreary.

We must work as a seller community to pivot and adapt. It forces us all to get better at inventory management, especially regarding thinning out our excess inventory. We do hope Amazon adjusts these restrictions for the good of the seller community. Meanwhile, streamlining your inventory management and logistics strategies and getting your FBM fulfillment in place are the two main things to focus on for long-term sustainability in today’s storage-crunched climate.

Future Amazon Restock Limits Updates

A common question I get is, “When will Amazon restock limits be lifted?”

Amazon says that these limitations will change, but that doesn’t mean all of the limitations are going to end. Storage limitations will always be in place to some extent.

In fact, Amazon promised to announce some new changes coming up in December of 2021. We keep a close eye on this, so subscribe if you want us to keep you updated.

We’ll notify you when Amazon Restock Limits change, when we discover new workarounds, and when we create new software features to automate things to make them easier and more manageable for you.

GET SOFTWARE UPDATES ABOUT

AMAZON RESTOCK LIMITS

We’ll let you know about our software updates and big Amazon updates.

Need more information?

- Send Message: We typically reply within 2 hours during office hours.

- Schedule Demo: Dive deeper into the nuances of our software with Chelsea.

- Join Live Upcoming Webinar: New to Amazon inventory management? Learn three inventory techniques you can implement right away.

Get Started

Get Started

hello how do I turn the NARF program off?

Hi Evan,

To unenroll in NARF (North America Remote Fulfillment) you will want to go to the remote fulfillment page here: https://sellercentral.amazon.com/rafn/inventory

Then click the Program Settings link at the top right. You will then see an option to “Unenroll from Remote Fulfillment with FBA). Click this and confirm “Unenroll”.

Hope that helps.

Cheers,

Chelsea, SoStocked

Hi CHELSEA

I have unenroll in NARF (North America Remote Fulfillment) in my AMZ US account, and have yet seen any changes to my restock limits, is it something i should see immediately, or is it takes time till the next amazon restock evaluation?

in general i have 5000+ SKUs in this account, and i have severely affected by the last amazon changes and new limit calculation metric, so i am trying to find the best and fastest solution for this issue, as my sales dropped in more then 60 % since these changes took affect in Jul of this year.

i must add and say that your last article on this matter is the most professional and detailed article i have encountered with online so far, as all the rest simply provides an information that is already known to everyone, without any real suggestions and new information as yours.

i really glad to encounter with it, and wish you all the best with the new inventory tool.

i will surly try it our at some point, as currently i cannot ship anymore units to the FBA, and have to find a fast solution to more then 25,000 of overstock units in this account.

thank you, and hope to hear from you soon.

Kind Regards,

Doron.A

Hi Doron,

Yes the reset is something that you would see rather soon after. It is also possible that you may have shipments in Working status or Shipped status that are adding to your utilization count.

If you send me a video to [email protected] to show me what is happening, I may be able to more easily diagnose your particular issue.

Lastly, check out the video I recorded on the new hack that people are using to increase restock limits here: https://www.sostocked.com/amazon-restock-limits/ It is the first video in the article.

Hope all that helps.

Best,

Chelsea

There is a ton of really valuable information that I get from your articles – so thank you! please keep them coming. A lot of the information you share I cannot find elsewhere!

Happy to hear you find our posts valuable.