How to Automate Amazon Inventory Forecasting For Accurate Reordering

The Essential Amazon Inventory Forecasting Setup Guide

Now, more than ever, getting your Amazon inventory forecasting right is extremely important for your business. More and more businesses have been taken out in these past couple of years due to improper inventory management.

Add to that the fact that lead times and the cost of shipping have increased exponentially. Profit margins are shrinking, which means the margin of error has become quite slim. It is more vital than ever to make inventory control a top focus within your business because you can’t afford not to.

Whether you have been selling online for years or you’re just getting into the eComm physical products game, developing a solid plan and processes for your inventory management can be a daunting task, one that typically involves incessant Amazon report downloads and hours buried in complex, formula-laced spreadsheets. And often it feels like you’re guessing.

But by putting a smart inventory system in place, you’ll be able to cut down on time, guesswork and stress and feel more confident in your inventory planning and decisions.

Better than that, you’ll finally be able to offload inventory tasks to your VA or inventory manager because you’ll have created a sound structured plan that they can follow.

I’m here to help you to understand how to build a solid foundation with the right inventory tools and techniques so you can great a forecasting process that truly works for you and that you can systemize your order and transfers and avoid those dreaded and expensive stockouts.

The goal is to create an inventory management machine that takes much of the guesswork out of your forecasting, helps you to track and account for all inventory across all marketplaces, suppliers and warehouses, and gives you a faster, more automated system. The end result should be streamlined reordering and transferring, improved in-stock rate and increased profitability and efficiency. So what are you waiting for? Let’s go!

In this Amazon Inventory Forecasting guide, we’ll take a look at:

- Amazon Inventory Forecasting Examples

- The Importance of Inventory Forecasting For Amazon Sellers

- Restock Limits, the Supply Chain and Inventory Forecasting

- What is Amazon Inventory Forecasting?

- How Does Amazon Inventory Forecasting Work?

- How To Use Inventory Forecasting Software To Automate Your Inventory Processes

- Best Practices for Inventory Forecasting

- What’s Your Next Move?

Amazon Inventory Forecasting Examples

Looking to save some time? Here is some quick insight into the #1 reason forecasting goes wrong, along with some other quick forecasting tips that should help put you on a better path quickly.

Don’t forget to read on though, as there are many other tips and techniques in the rest of the article that should be extremely helpful to you.

Quick Links to Resources Mentioned in the Video:

- Find out more about buffer stock.

- Download our Inventory-Minded Marketing template.

- Learn more about how SoStocked can help by booking a live demo.

Read on to learn more about how proper inventory management can save time and improve your profitability.

Amazon Inventory Forecasting Examples

Below are a few examples of different use case scenarios so you can get an idea of how different product situations are forecasted.

We will talk a lot about sales patterns and velocities in this section but be sure to read on further down to truly understand how velocities should be calculated as improperly calculating velocities can lead to over-ordering or stock outs faster than anything else.

New Products

New products present their own challenge in that you do not have current data to forecast with. Most forecasting is based on past data so the challenge in forecasting new products is that there is none or very little.

Fortunately, we live in the Amazon age and there are many tools available to help us to determine the sales velocity of a particular product. Looking at the estimated monthly sales volume of other similar products can help us to determine what we might expect to sell. Then, we should determine what percentage of those sales we think we will be able to take.

Once that baseline of a steady sales velocity is determined, we then need to decide how aggressively we would like to launch. Some Amazon pros set the rule of thumb for lanches at 50% of the average sales for that product. For example, if the top-selling product is doing 4,500 units per month, 50% would be 2250 units. Divided by 30 days, that is 75 units per day. So your launch should push for 75 units per day. If you do a 7-day launch, that would be 525 units. From that point, you would add your steady sales volume as calculated above to ensure you have enough inventory for the successful launch and maintenance of your new product sales.

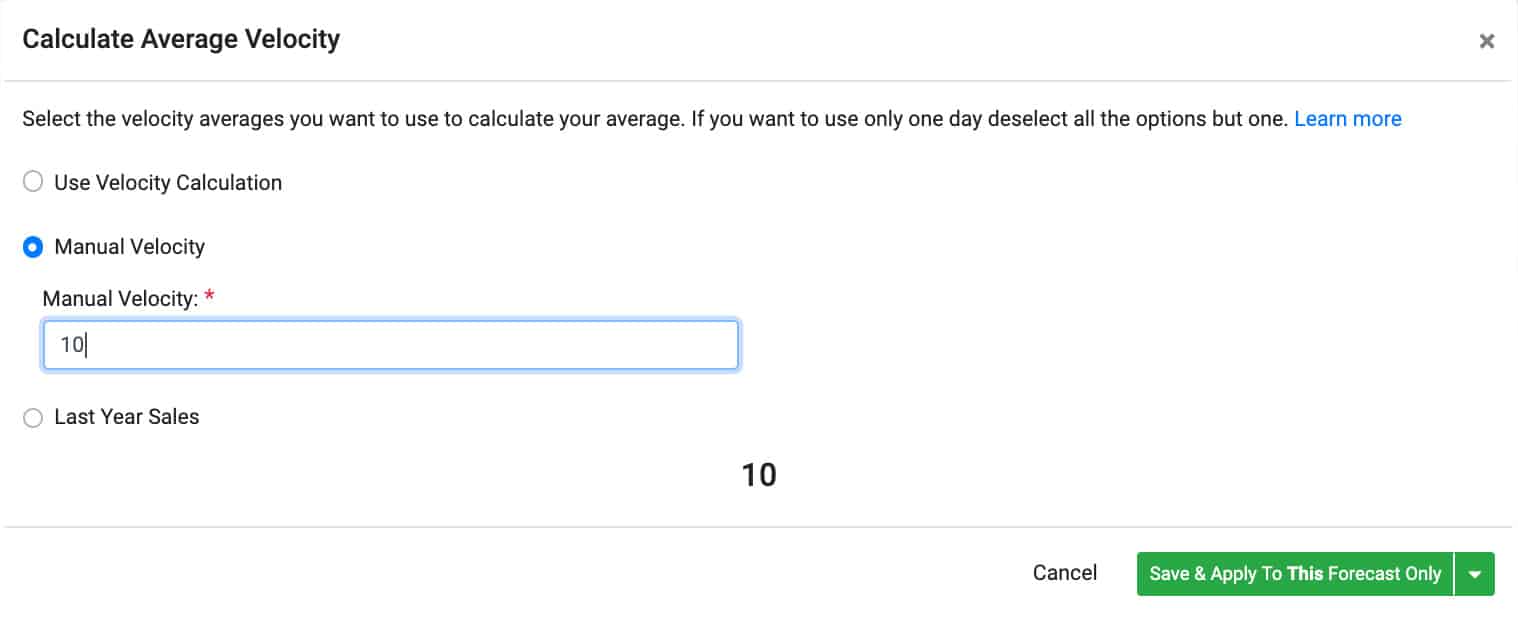

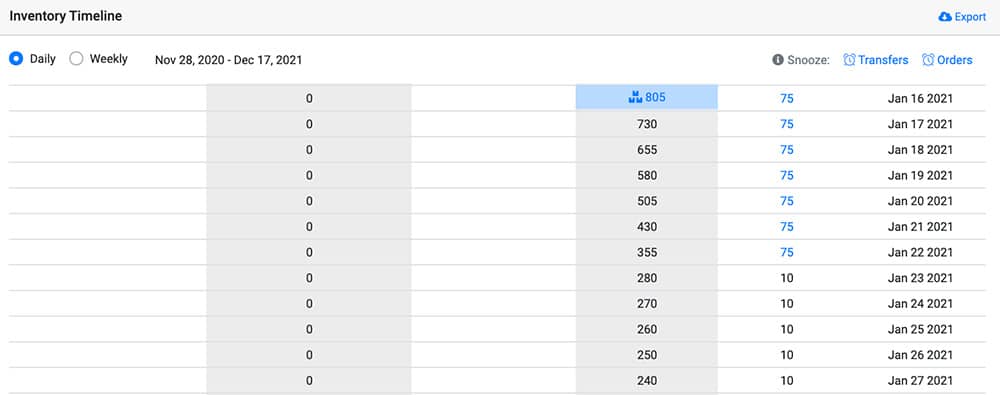

For this reason, in order to forecast new products, it is important to have a manual velocity to override any other sales data that may be computed.

This way you can disregard the sales made during your launch and build in a more steady sales pattern, then simply layer the launch units on top of that.

Steady, Established Products

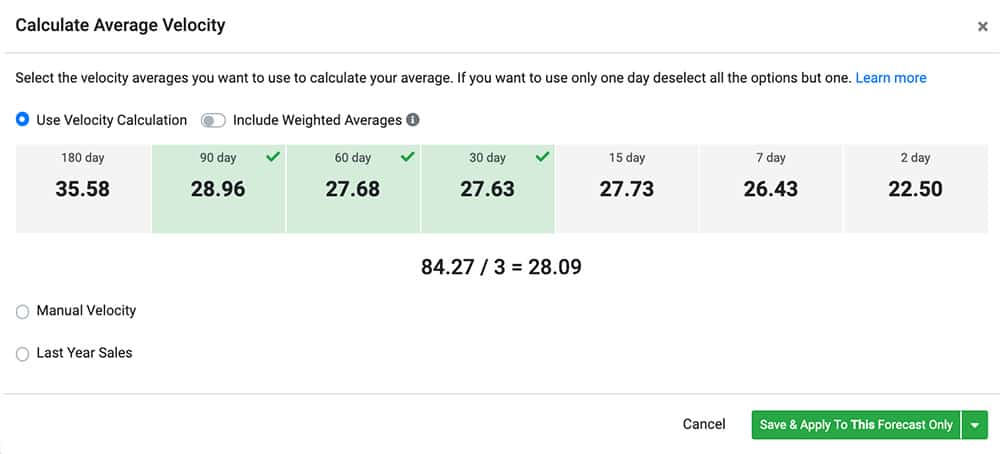

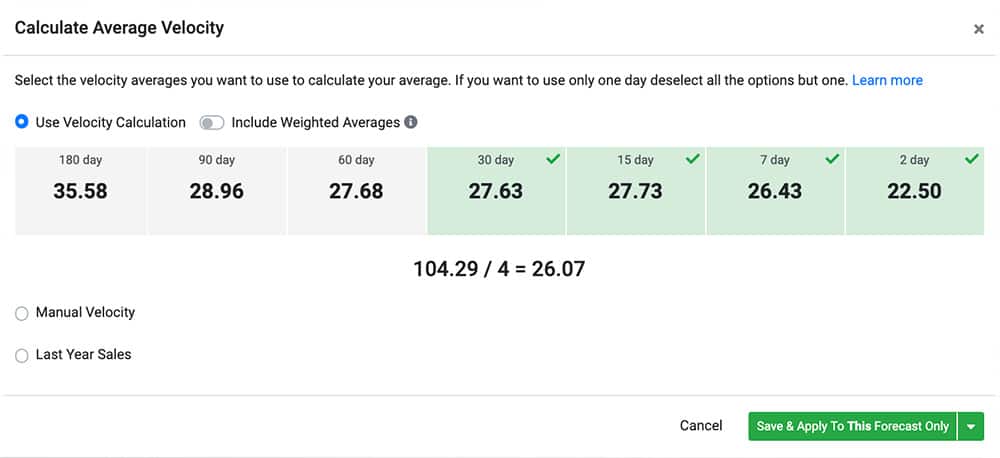

When selling products that have steady, established sales that do not fluctuate from season to season, looking at a longer term velocity such as 30, 60, or 90 days tends to be a good rule of thumb. Now if you have products that are fairly steady for most of the year but then tend to sell well, say, during Christmas or Summer, it may be that you actually need two different approaches to your forecasting throughout the year.

During your steady sales periods, you’d want to opt for the 30, 60, or 90 days as mentioned above, or a combination of those such as an average 30, 60, and 90-day velocities.

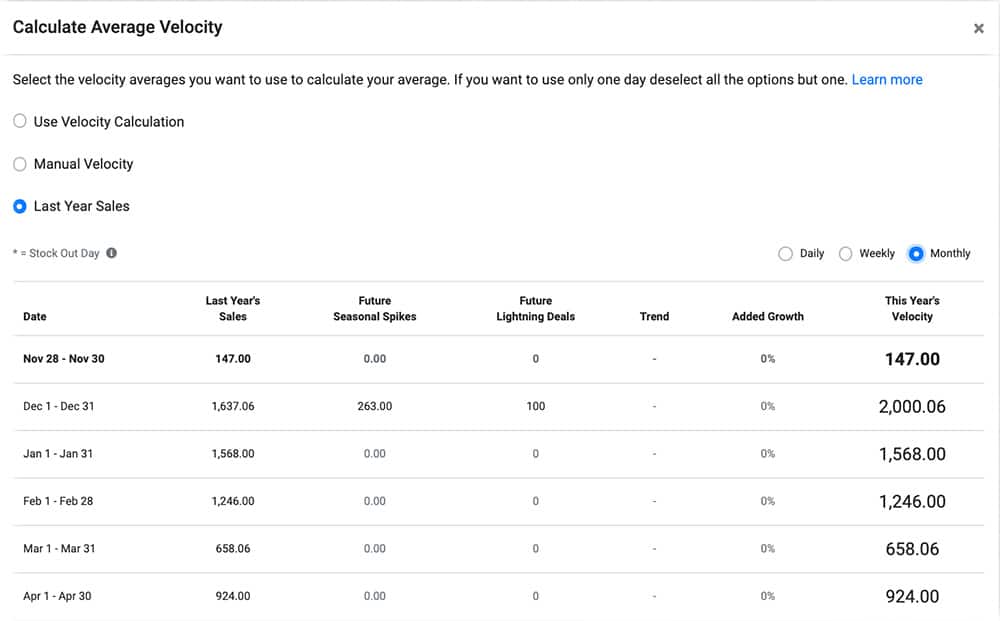

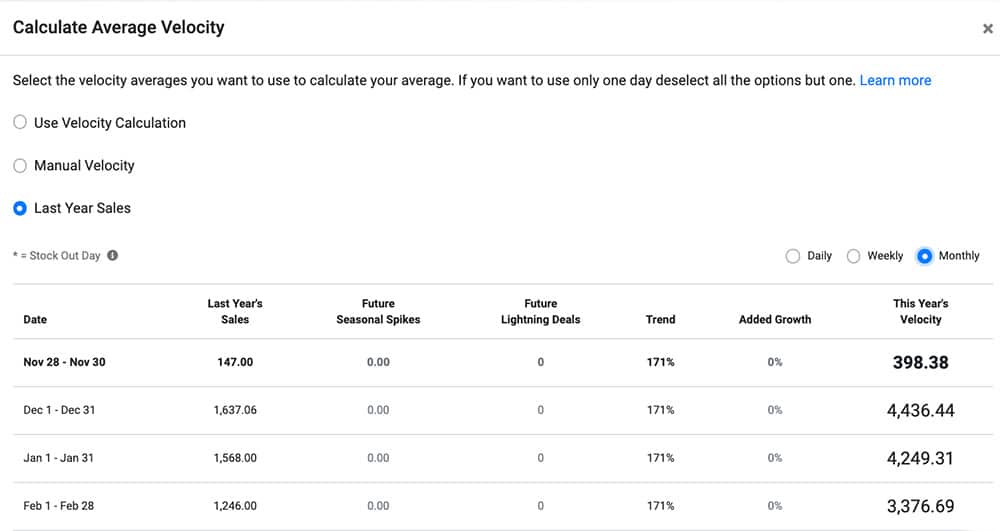

Then, when it comes time to plan for your holiday or Summer sales season, simply switch to using Last Year’s Sales data.

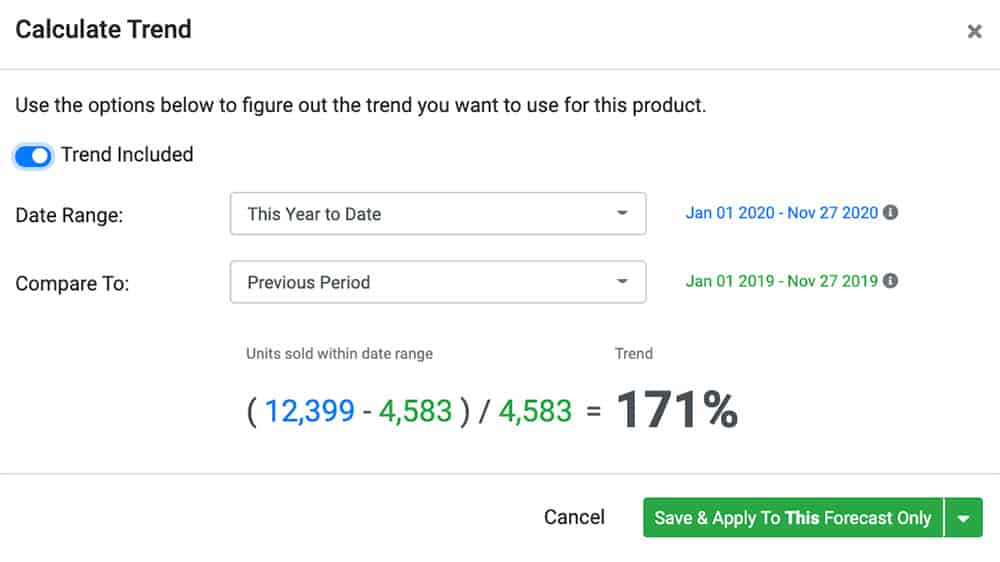

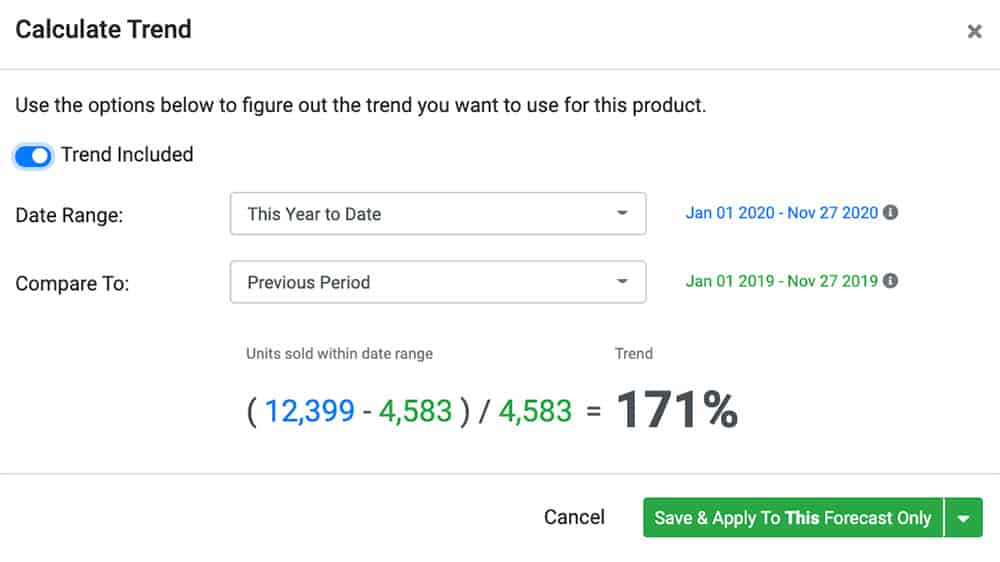

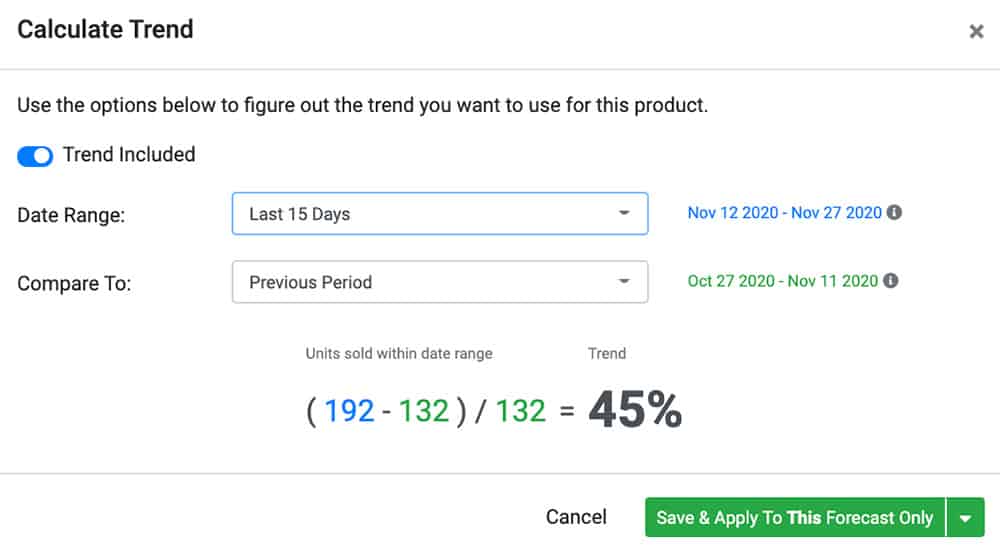

You can even consider adding growth trends on top of last year’s data to further improve the accuracy of your projections. A favorite of many sellers is using the Year-to-Date growth factor layered on top of Last Year’s Sales.

Then, of course, after your sales season is past and you start coming into your normal sales again, you can switch back to your 30-day sales, making sure that none of the heightened sales data is captured within that 30 days. Some sellers even opt for the 15 or 7-day sales period until they have a full 30 days of normal, non-seasonal sales.

Products Where You’re Sharing the Buy Box

When sharing the Buy Box, as with selling using the wholesale model, sales tend to be less steady and tend to fluctuate much more frequently than with a product that you consistently own the Buy Box on such as a Private Label product. For this reason, using a more short term sales velocity period tends to make more sense. Many sellers using this business model tend to use the 30, 15, 7, and even 2-day sales calculations and often a combination of these.

This is to allow for the fluctuation of the market as, generally, there is much more fluctuation and there is also more flexibility in wholesale restocking, as the lead times tend to be much shorter at 1-2 weeks. This allows for faster response times in restocking and so looking at the more narrow time frames tends to improve accuracy on a shorter restock cycle.

Seasonal Products

As with steady, established products, seasonal products can utilize Last Year’s Sales data or a combination of Last Year’s Sales and Year-to-Date Trend data.

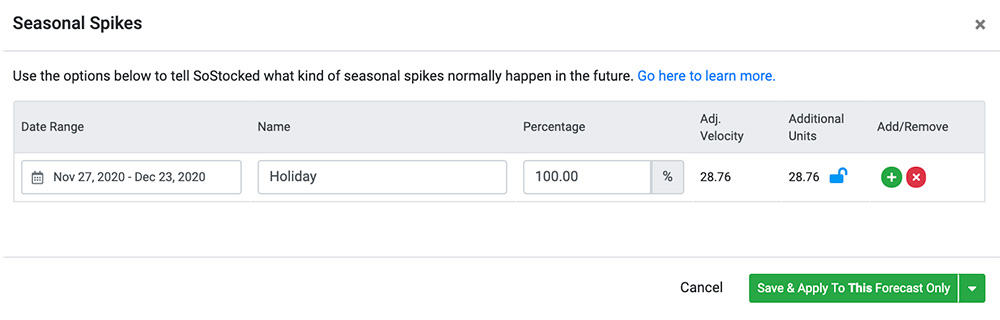

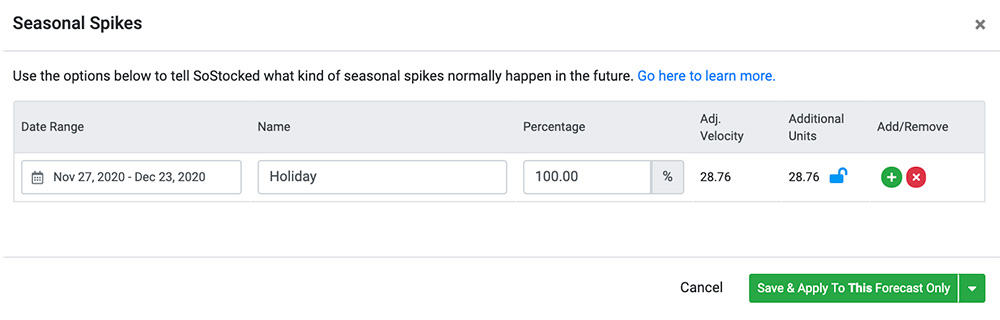

But what happens when you have no data from last year? In those instances, simply use this year’s data and add a seasonal increase or decrease as needed. For example, if sales in your category are expected to double during the holiday season, you can add a 100% increase starting on Black Friday and extending through to December 23rd

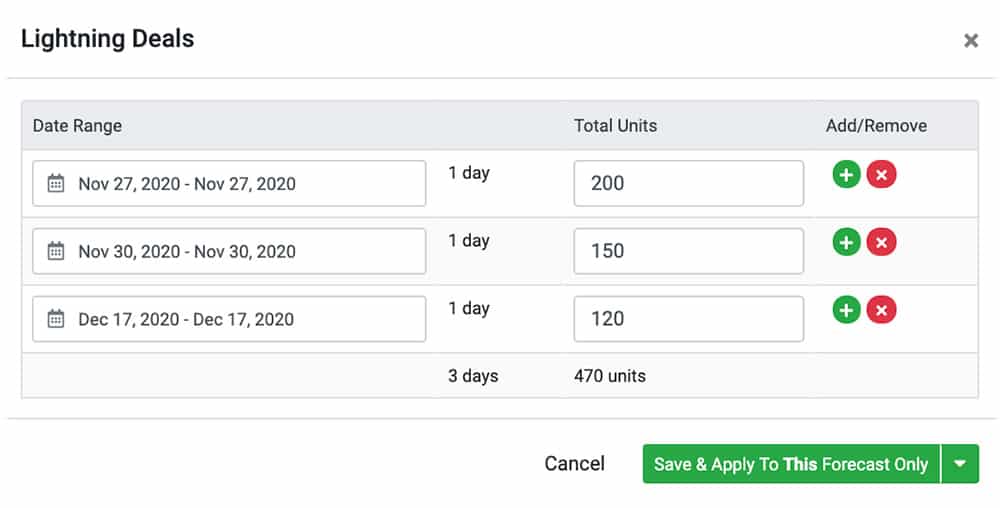

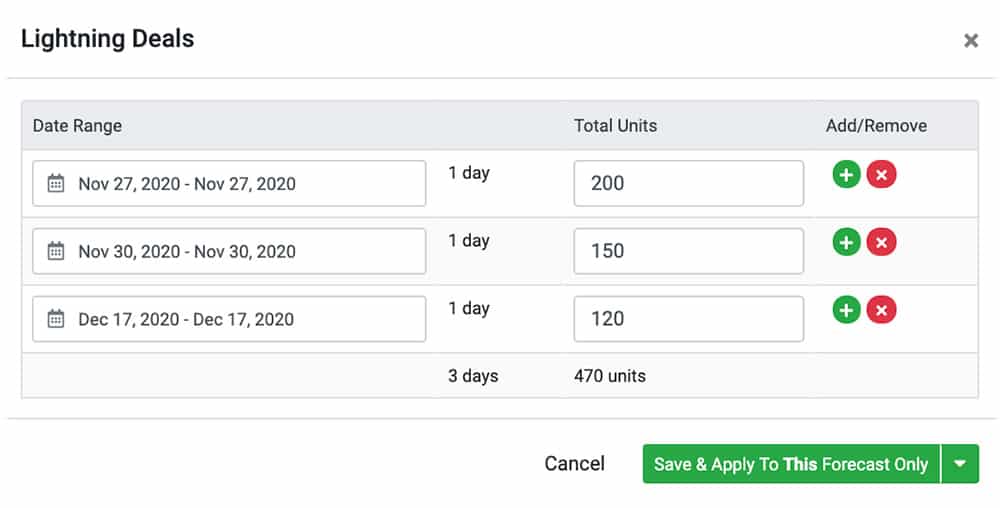

You can also add sales spikes for things like Black Friday, Cyber Monday, and any Lightning Deals you may have.

Steady Growth

For a product with steady sales and steady growth using Trends such as Year-to-Date or 90-day trends can help you to forecast potential sales demand.

Applying these trends will help you to forecast potential continued sales growth.

Accelerated Growth

For accelerated growth, using more short term trends, such as 15 or 30 days can serve you well.

This can sometimes be the best option for a product that is newly launched and gaining ranking rapidly before settling out into a steady, established product.

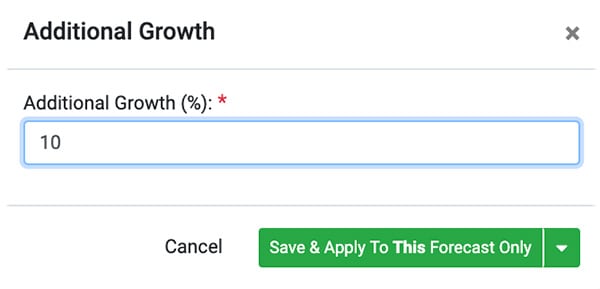

Planned Growth

Products with planned growth but without the trend data to support their growth can use a simple Additional Sales Growth increase. This would add a percentage to all sales on top of whatever velocity is being used.

This can be the best option for products you are beginning aggressive PPC campaigns for.

The Importance of Inventory Forecasting For Amazon Sellers

While it can sometimes seem obvious, it is valid to discuss why proper forecasting is important as there are other subtle or less obvious reasons for proper forecasting that are not often considered.

The Benefits of Accurate Inventory Forecasting

Inventory forecasting is important because it helps you to control your cash flow and improve your bottom line profitability by limiting stock outs, over-ordering, and expensive air shipments.

It is also becoming increasingly more important to the Amazon algorithm as Amazon continues to push its own policies toward inventory efficiency. The better you are at inventory management within Amazon, the happier Amazon is.

Minimize Stock Outs

Minimizing stock outs is important for a few reasons. First is the obvious, the revenue lost when stocking out has a direct impact on your bottom line. The second is the potential loss of page rank and subsequent cost of re-ranking your product. An additional impact comes in the negative effect on your Inventory Performance Index (IPI) score. Amazon’s algorithm does not like to see stock outs and can thus penalize your account by lowering your restock limits after a stock out, Something which could cause potential stock out cycles due to decreasing restock limits.

Staying in stock helps you to avoid all of this and that helps you to increase your bottom line.

Reduce Product Waste

Product waste, or inventory waste, is the waste within your business due to inventory that does not quickly turn over, or sell. This waste would include the wasted money spent on storage fees, the wasted opportunity due to tied up capital that could be utilized elsewhere, and any other waste that could occur due to the over-ordering of those products.

When you forecast properly you avoid all of this inventory waste. Less inventory on hand means less waste. The right inventory on hand means minimizing waste and stock outs while maximizing profit.

Reduce Inventory Holding Costs

Holding cost is incorporated into product waste but bears repeating. Proper forecasting and ordering means that your inventory efficiency improves bringing your inventory holding costs, i.e. storage fees, down. If you have to pay for 1 month of storage vs 3 months of storage, the profit per unit will be higher.

To sum it up, accurate ordering means more efficiency and less storage cost and, therefore, higher profits for you.

Less Guess Stress

Guess stress is real. Amazon sellers often put off reordering due to the added stress, frustration, and time. This procrastination can end up leading to ordering too late. Not knowing exactly what to do when placing your next order can add extra time, doubt, and confusion to your process.

When you have an organized and automated system, it tends to eliminate the guess stress and to take a lot less time; therefore, you order when you should, avoid stock outs, and keep your rankings and profits.

Maintain Ranking

When your product runs out of stock, it can start to lose page ranking rapidly. For that reason, keeping in stock becomes important beyond just the lost revenue. The cost of re-ranking a product added on top of the lost revenue can make stocking out a very costly mistake.

Increase Business Valuation

The better you manage your inventory, the less you stock out, the lower your storage fees, and the better your profitability. At the end of the day, profit is what investors look at when buying businesses. They attend to give a multiple based on the overall profit of the business. This means that your profit will help to determine the overall value of your business when it comes time to sell. Businesses tend to sell at a multiple of that profit. The more profit you keep in your business, the higher that valuation if you ever decide to exit your business.

Protect Your IPI Score

Amazon has been taking inventory management much more seriously these days. So seriously, in fact, that they’ve been essentially penalizing sellers who have trouble keeping their products in stock. They have been setting the amount of inventory you are able to send into Amazon FBA warehouses based on your total sales for a given period. This means that if you stock out, you will be selling fewer total units over that time period, and thus Amazon will not allow you to send as much inventory the next time around. This ties back into the need to minimize stock outs we discussed above. While staying in stock is just one factor affecting your IPI score, it can be an important one.

Pro Tip: Use an amazon forecasting software like SoStocked to accurately forecast orders and factor in things like past sales, future marketing, and seasonality.

Restock Limits, the Supply Chain and Inventory Forecasting

Other more recent factors that make accurately forecasting your inventory demand more important than ever are restock limits and supply chain constraints introduced with the onset of the Covid-19 pandemic. Two things which are proving to have long-lasting effects.

With the introduction of universal restock limit restrictions for all sellers across the Amazon FBA network in 2020, inventory forecasting has become more complex than ever, making good inventory management all the more crucial.

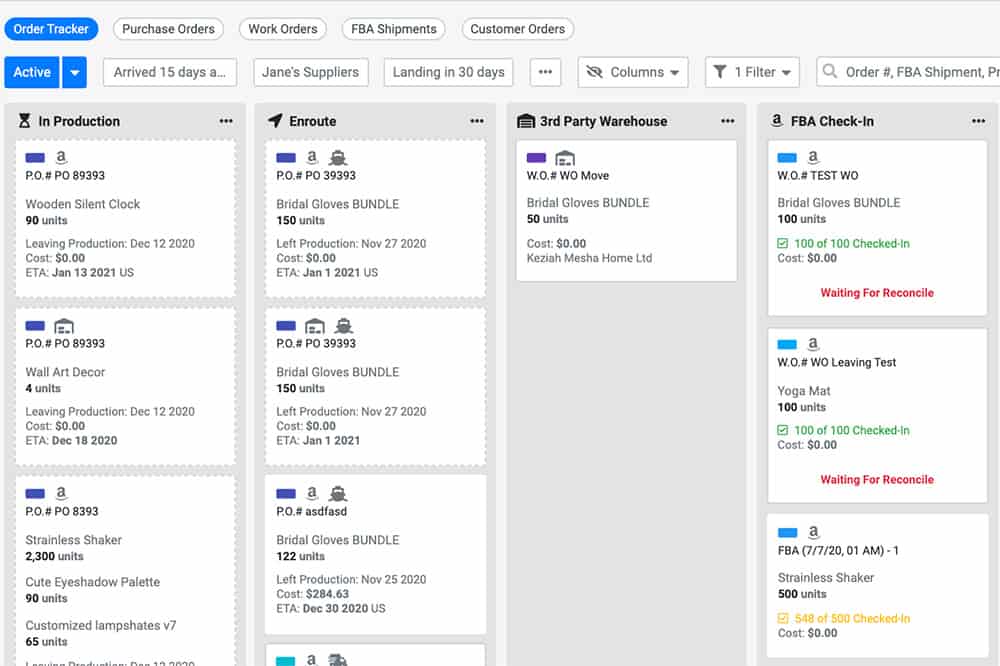

Many sellers have found themselves forced into storing excess inventory within third party warehouses and have had to send inventory into FBA from these warehouses much more frequently.

In the past, inventory turnover, one of the key yardsticks in determining whether a business was doing a good job with managing inventory, was not a major concern for Amazon sellers because they could generally send in as much inventory as they wanted to without issue.

The post-Covid shifting of Amazon’s inventory policies have forced sellers to become better at managing inventory, a skillset most sellers had not, to that point, had to hone.

Therefore, inventory management has become much more important than before.

Add to that the increasing lead times and unpredictability of the supply chain and techniques like incorporating a buffer stock into your process become more crucial than ever. It’s sort of like having a rainy day fund for when your car breaks down. Supply chain emergencies are much better weathered when you have an extra stash of inventory to float you until your inventory finally arrives.

The habits we lay out below are essential to any inventory-based business at any time, but now more than ever it is becoming clear why running your business on sound inventory principles and practices is vital to the health and stability of your business.

What is Amazon Inventory Forecasting?

Amazon Inventory Forecasting is the action of determining what inventory to order or reorder. Below are some methods and things to think about when forecasting your Amazon inventory.

Are You Selling Goods As Fast As They Are Stocked?

This is what is known as sell-through or turn over. You want to increase the rate of sell-through. You do not want to take 5 or 6 months to sell through an item as this means 5 or 6 months worth of storage fees and 5 or 6 months of capital that is tied up in inventory that is not moving.

To optimize this sell-through rate, you want to determine how best to avoid storage fees and unturned capital and limit these things as much as possible. For example, if you are charged for storage each month, you should potentially have a goal to turn over your inventory monthly or as quickly as possible.

Inventory Management vs. Inventory Forecasting

While inventory management and forecasting tend to go hand-in-hand, they are not the same thing. Forecasting is the act or process of determining how much to order to maintain optimal levels of inventory.

Inventory Management is the full function of ordering, storing and selling through your inventory. Included in this could be the management of raw materials, sub-SKUS, or components for kitting/bundling, and the finished, sellable product. Warehousing, kitting, and prep are also part of your inventory management system.

What is Demand Forecasting?

Demand forecasting is the method of trying to predict customer demand for your products in order to calculate proper order quantities and timing. While past sales may have some bearing on demand, it is not based on actual orders or sales but on potential future sales.

Sales Forecasting vs. Demand Forecasting

The main difference between sales and demand is that sales are actual past or current orders made. Current sales could be in the form of pre-orders that have not yet been fulfilled or wholesale orders requested in the form of invoices that need to be filled.

All that said, there are two types of forecasting which should be considered as part of your overall forecasting process.

Demand, as opposed to sale, is what customers want. Demand can change overtime. Further, demand could be outwardly affected, whereas sales can potentially be affected internally.

One of the things that could outwardly affect demand would be where your product is in its life cycle. For example, just because your product was all the rage and trending last year, does not mean it will perform the same this year.

Economic conditions can also impact demand. If you have a premium product and the economy goes through a recession, customers may tighten their belts and stop purchasing your top line products, opting instead for cheaper versions.

These are the types of things that could affect demand and should be considered when doing demand forecasting.

When it comes to Sales Forecasting however, historical data, in part, guides your forecasting. The other elements, however, that should factor into your calculations would be things that you can help to control internally.

Some of these things are sales, promotions, coupons or sales offers you plan to run. Essentially, sales forecasting would include past sales data to help to predict future potential sales, plus the marketing events you have planned that could increase the sales above this point.

What is Inventory Planning?

Inventory planning is the process of determining optimal levels of stock and the best timing for placing orders.

In order to do proper inventory planning, you should consider weaving demand forecasting and sales forecasting seamlessly together to help you to accurately predict based on past sales, potential changes in demand, and future planned marketing events.

This will help you to determine a reordering schedule that includes ordering deadlines and quantities. It is wise to do 3, 6, or even 12 months of inventory planning in advance. Of course, nothing would be set in stone until you actually place your orders as velocities and plans fluctuate over the year but it would give you a good estimate of inventory needs and cash flow. It is also very helpful to provide your suppliers with this estimated reordering schedule so they, too, can do their own inventory planning for raw materials and labor needed to fulfill your orders.

How Does Amazon Inventory Forecasting Work?

Learning sound inventory forecasting techniques helps you to build the foundation for a system that will help you to place orders that are right for your business and to off-load tasks to your VAs that you don’t want to do or don’t have time for.

How To Fix Inventory Problems

The three main inventory problems tend to be over-ordering (which produces product waste), under-ordering (leading to stock outs), and ordering too late, which also can cause stock outs.

The three most important “fixes” to these top inventory problems are:

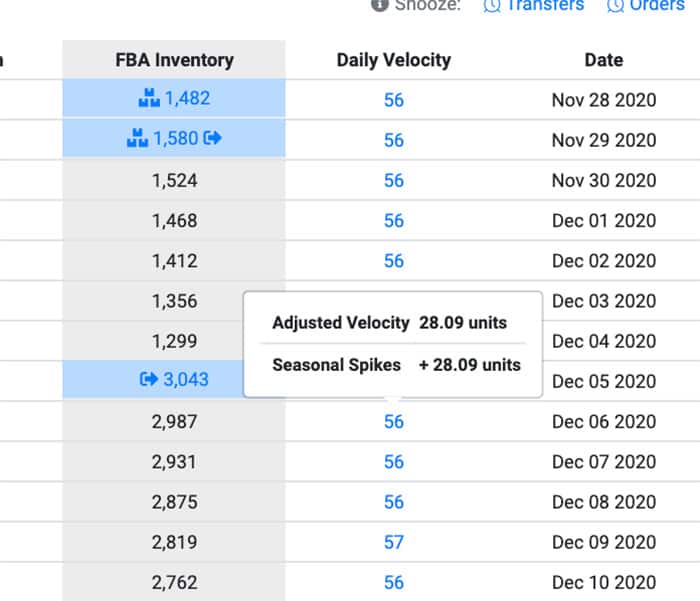

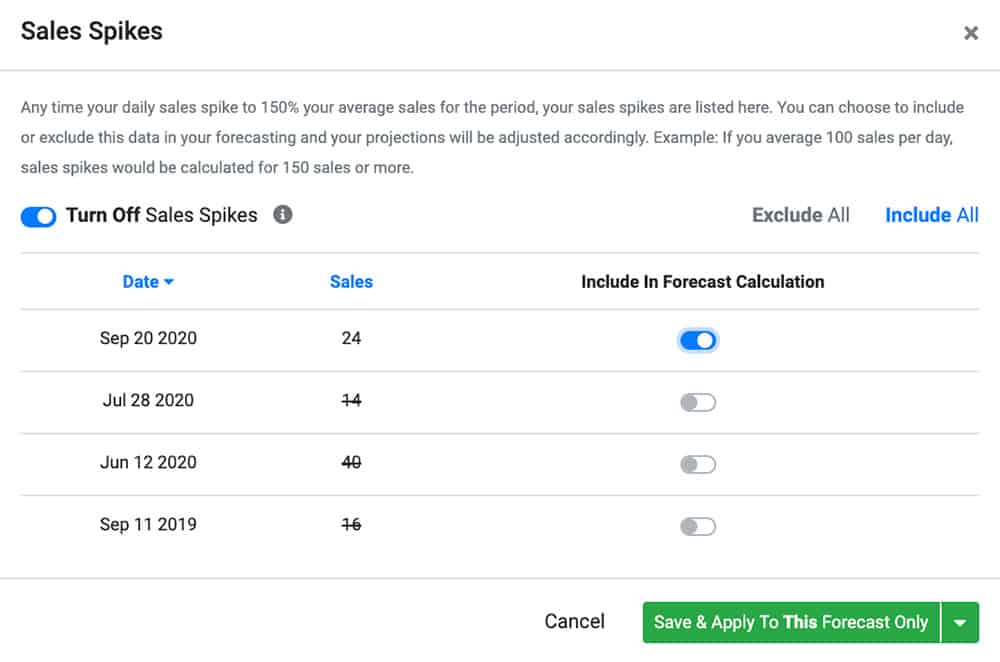

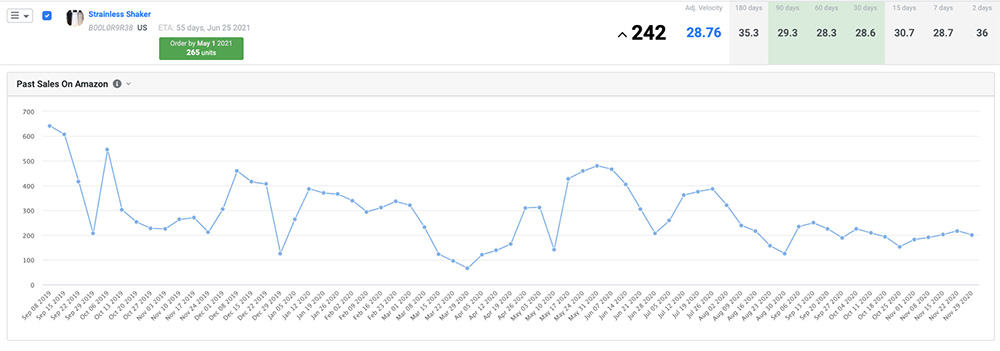

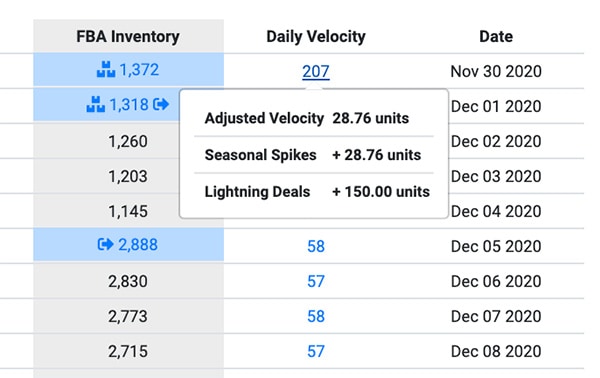

1. Removing Sales Spikes

Sales spikes in your sales history that will not be guaranteed to repeat themselves in the future need to be factored out of your daily sales velocity. So, for example, if you had a Lightning Deal last year that you will not have this year, you need to be able to remove that. Not removing these things can be a prime contributor to over-ordering.

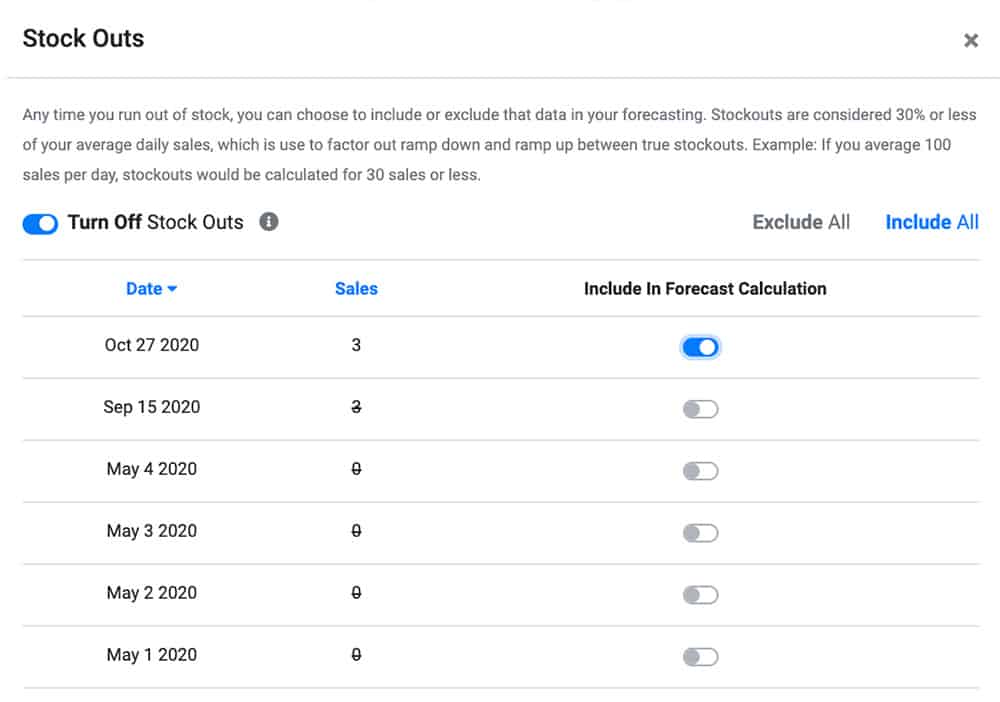

2. Removing Stock Outs.

Not eliminating stock outs from your forecast calculation can result in the opposite problem. If you stocked out 10 out of the last 30 days but are just using total sales to determine the next 30 days of stock, you will end up ordering the same amount that caused you to stock out, triggering a potential stock out cycle. You need to determine what your average daily sales would have been without the stock outs so you can be sure to order the correct amount of stock for next time.

Factoring out things like sales spikes and stock outs is what we call Adjusted Velocity. You are adjusting the numbers to remove any of the outliers that do not help you to order the correct amount of stock the next time around. Adjusting these numbers gives you a better idea of what should realistically happen in the future if all goes to plan.

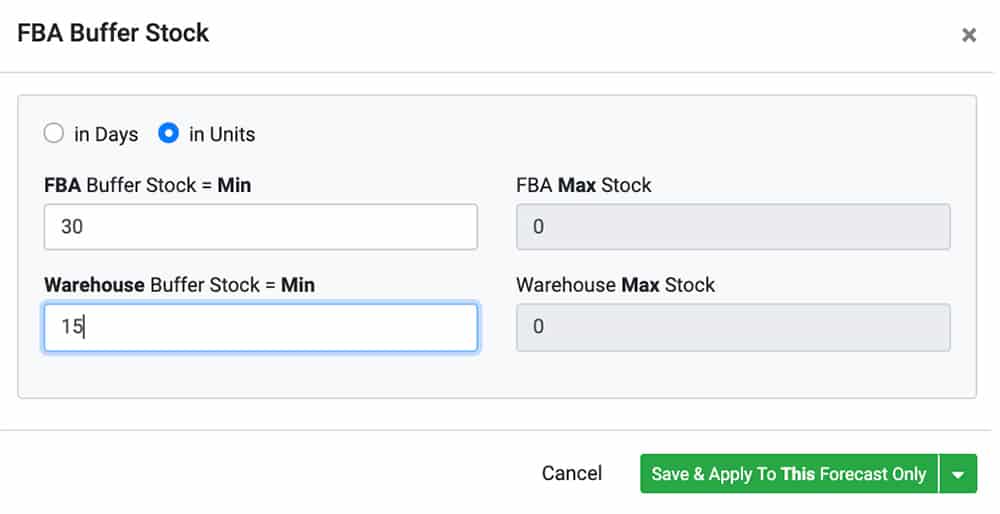

3. Adopting a Buffer Stock.

Buffer stock, also called safety stock, is a little bit of extra stock that you keep on hand as a cushion in case anything goes wrong with your order and it arrives late. It is like the Empty light on your car when running low on gas that warns you to fill up before you run out so you have enough time to make it to the station.

The best way to calculate buffer stock is to use a multiple of days, such as 30 days of extra stock on hand so that your order arrives by the time you hit 30 days left of stock, not zero days of stock.

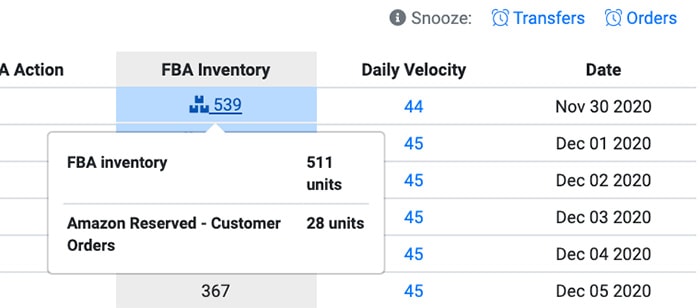

How to Calculate Inventory

To properly calculate current inventory, you must factor in several things to ensure all of your current stock is accounted for.

To start, you must get the proper inventory count at Amazon. This is a combination of (1) Available Inventory, (2) Reserved Inventory minus Customer Orders, this is all inventory that is being processed within or transferred between fulfillment centers, and (3) and Inbound FBA Shipments that have not yet been checked into Amazon.

This will give you an accurate account of inventory connected to Amazon.

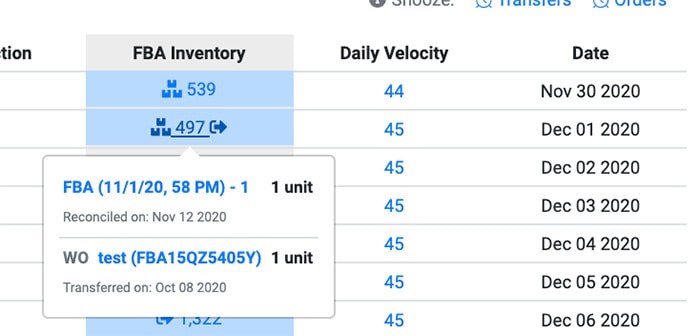

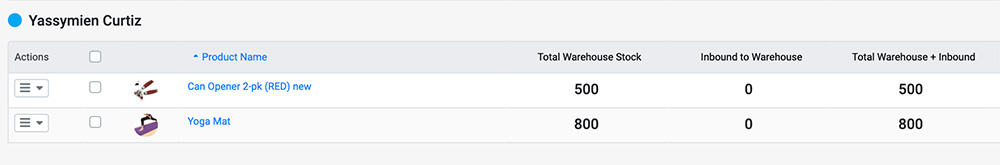

However, there are two other potential factors to account for: open Purchase Orders and 3rd Party Warehouse Inventory.

You must also account for any Purchase Orders that are in production or en route to either your warehouse or Amazon. NOTE: Be careful not to double count any Amazon Inbound Shipment inventory that is connected to a pending Purchase Order.

All of this should be tracked by potential arrival dates to ensure there is no gap in available inventory.

Then, any inventory you are currently storing at 3rd Party Warehouses should be accounted for as well.

With all of these elements in place, you should have the starting point to begin forecasting your inventory orders.

How to Forecast Inventory

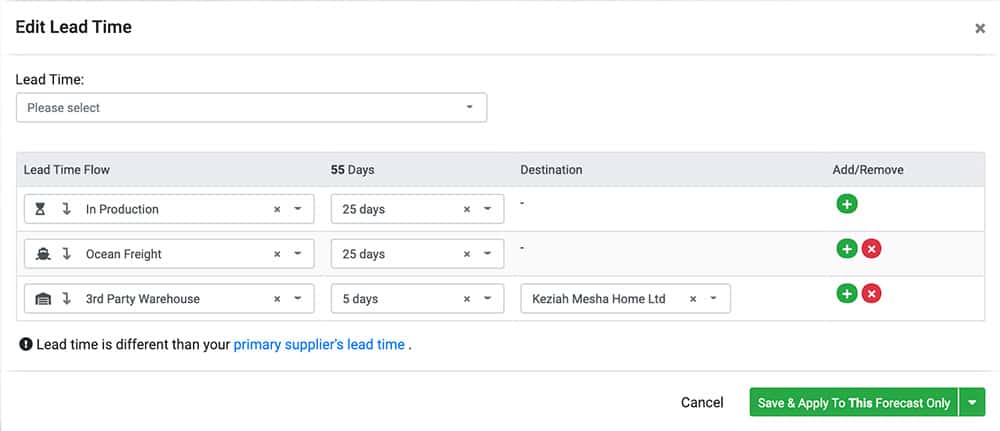

Once your inventory has been properly calculated and accounted for, you need historical sales data along with supplier lead times and order frequency or an order schedule as the main elements for forecasting.

Historical sales data can be pulled from your Amazon sales reports via download or directly from an Amazon API connection like SoStocked does.

Your supplier lead times can be gotten from your suppliers and freight forwarders by asking how long your items will take to produce and to ship. Currently, due to all of the delays and problems arising along the logistics and supply chain network, asking your suppliers and freight forwarding companies more frequently for updates on their lead times is an important practice which will help you to forecast more accurate reorder points.

Order frequency is often based on Minimum Order Quantity and optimal shipment sizes such as full container loads. It should also be made, in part, by determining how quickly you can turn, or sell through, your inventory. The faster your sell-through, often the lower your storage fees.

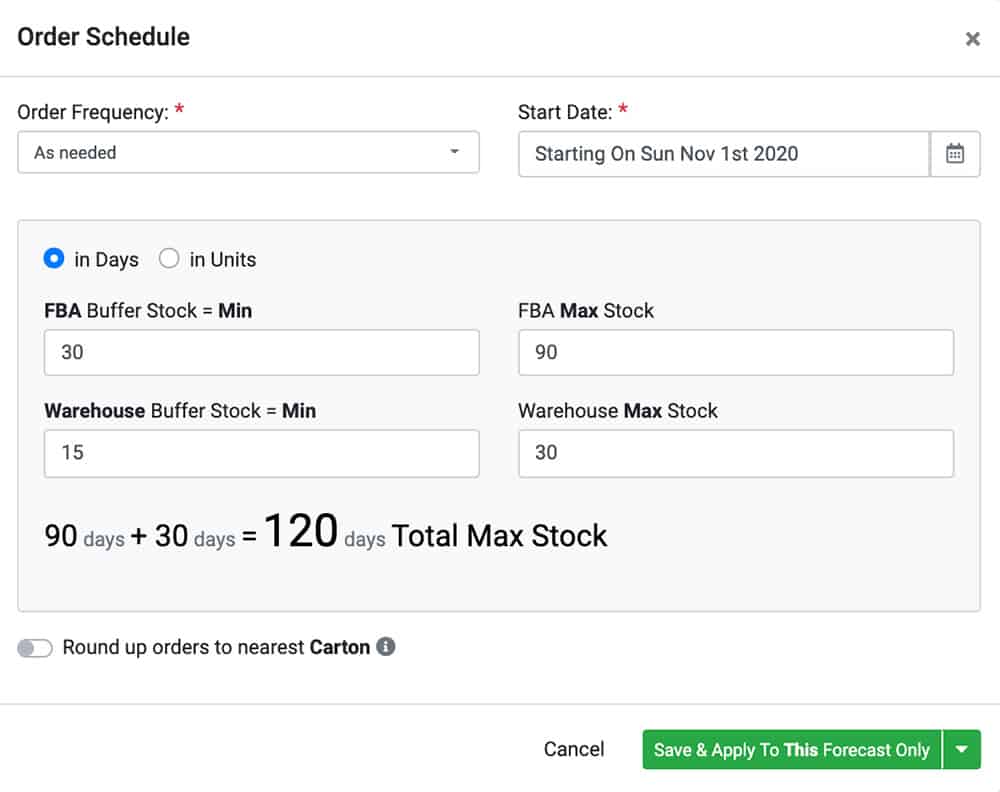

The more sophisticated way of setting your order frequency is to use what is known as Min/Max Restocking.

Min/Max Restocking is a way of setting a minimum and a maximum range that you will always stay within.

For example, if your minimum is at 30 days, you will be prompted to order or transfer so that your inventory arrives before you hit 30 days worth of inventory. If your max is set to 90 days, you will be told to replenish up to 90 days each time you restock. So you will replenish to 90 days worth of inventory, then sell through to 30 days and restock back up to 90. Your lead times and transfer times should be baked into the equation so that you are told to transfer or order in time. So if you have a 30-day minimum, or buffer stock, and your transfer time is 10 days, you will be told to transfer 40 days before you run out of stock.

You should also consider setting a minimum and a maximum for your warehouse inventory just so that you keep an extra cushion available to hand.

Lastly, setting your transfer frequency if you are using a 3rd party warehouse to store excess inventory will also help you to systemize and automate this process. The same min/max techniques that are applied to order frequency can be applied to transfer frequency, although the lead time will, of course, change.

The Most Important Metrics in Inventory Planning

The most important metrics for inventory planning are:

- Total Inventory, which includes:

- Amazon Available Inventory

- Amazon Reserved Inventory minus Customer Orders

- Inventory en route to Amazon not yet checked in.

- Inventory at your 3rd party warehouse(s)

- Inventory in production

- Inventory en route to warehouse(s)

- Adjusted Sales Velocity, which includes:

- Daily Sales Velocity

- Adjusted for Sales Spikes

- Adjusted for Stock Outs

- Adjusted for Deep Discounts

- Trend (optional)

- Order Schedule using a set frequency such as monthly or variable frequency using Min/Max Restocking.

- Transfer Schedule, same as above.

- Seasonality, any predicted sales increases or decreases based on historical patterns or demand forecasting.

- Marketing Events for sales forecasting such as:

- Lightning Deals

- Email Campaigns

- Changes to PPC Campaigns

- Coupon Promotions

- Influencer Promotions

- Any other planned marketing campaigns

- Cash flow or cash on hand, to ensure you can afford the orders that need to be placed.

Knowing all of the above will help you to properly build out a sound inventory management system to stay in stock, reduce product waste, and avoid expensive, emergency air shipments.

How To Use Inventory Forecasting Software To Automate Your Inventory Processes

Using an Amazon inventory management software can be a game-changer as it can handle, process, and sort data much better than simply using spreadsheets and downloaded Amazon reports.

However, it is extremely important to know how the software works, what algorithms it is using, and how it is computing your data. A software that is too secretive about how it looks at your data or that uses the wrong calculations may not be as helpful as you think and could actually be more harmful than helpful. An inventory software should be able to do all we discussed in this post. It should be fully transparent, fully understandable and fully customizable.

It should allow you to remove sales spikes and stock outs and not just look at inventory on hand but should treat listing suspensions as stock outs as well, something most inventory software systems don’t currently do. It should be able to handle your orders and your transfers and should allow you to add marketing events into your inventory planning.

All that said, with the right inventory software, what benefits can you expect?

Setting up things such as buffer stock within a software will mean that you can get notifications to place orders and transfers well before you run out so you can avoid stock outs and expensive air freight.

You will have an accurate accounting of all of your inventory in one place to track all shipments, inventory, and projections so that you are always prepared.

SoStocked does all of these things and more. It was designed by an Amazon seller and has gone through many updates and improvements based on the feedback from hundreds of successful, seasoned sellers.

SoStocked users have streamlined their processes, cut many hours out of their weekly and monthly management, and saved money by avoiding stock outs and air shipments.

Set up within SoStocked can be as quick as a few hours following our in-app guides and tutorials. After your account has been set up, you can receive daily or weekly emails when any orders or transfers are needed. A great system, long term means automation, and SoStocked was designed to help you with just that.

Best Practices for Inventory Forecasting

To wrap up, below are some of the additional best practices that we and our users have adopted to truly ensure an inventory plan that works.

Sync with Marketing and Accounting

One of the primary reasons for inventory issues is marketing in a vacuum. By this is meant that sellers often begin on a successful marketing campaign but don’t think to vet this campaign against their inventory to see how inventory levels will be affected and whether they can keep up with the marketing changes. A good marketing plan then can turn bad real quick when it stocks out your best seller.

Adding your marketing campaign projections into your inventory plans helps you to see whether your plan will cause you to stock out. Using this data, you can adjust your marketing accordingly to ensure you stay in stock and increase future orders to keep pace with growth.

To take it one step further, checking with your accounting team to make sure they will have the cash on hand to afford future inventory orders helps to round out the entire sales cycle so that everyone is on the same page and working together for the success of the company as a whole.

What is “Good Data”?

This is just a final plug for using Adjusted Daily Velocity. Using good data rather than gut feel helps you to place orders appropriate to your business. This means that you are not putting sales spikes and stock outs into your data and repeating past mistakes such as over and under-ordering.

You also need to ensure that you are keeping real-time stock levels so that you don’t double count or miss any inventory, which can also mess up your order amounts.

Always Have a Backup Plan

Lastly, always have a backup plan. Don’t rely on Amazon to be the keeper of your business. If they lose inventory or take forever checking it in or restrict the number of units you can send, you may find yourself facing an inventory nightmare that can really have a harsh impact on your bottom line.

For that reason, making sure you have a 3rd party warehouse and distribution system set up can help you to keep sales coming in even when Amazon can’t seem to properly stock your items into FBA.

Like I always like to say, even if Amazon is your only sales channel, it shouldn’t be your only distribution channel.

Inventory management can seem complicated, with lots of moving parts, but getting the foundation in place can mean you create a system that works for you and can greatly improve your bottom-line profitability. After all, it’s not what you make, it’s what you keep.

What’s Your Next Move?

Now that you have a deeper understanding of inventory management and forecasting processes, it’s time to start thinking about how to put these plans into action in your own business.

I hope this primer was helpful and provided you with a lot of great ideas that you can implement to make your business run more efficiently and, above all, more profitably. Putting in more structure and order will help you to stay in stock and to avoid the costly mistake of over-ordering which, in turn, improves cash flow and increases your margins overall.

So where do you go from here? Here are some things I suggest taking on right away to most dramatically impact your processes and improve your inventory health both immediately and long term.

- Start by focusing on what I feel are some of the most important best practices for inventory management: daily adjusted velocity, buffer stock, and min/max restocking.

- Automate more of your processes by signing up for an inventory management and forecasting software like SoStocked.com.

- Bring your VAs and inventory management team on board by continuing to systemize your reorder and transfer process. Our Inventory Management Training Guide, filled with helpful resources, can help to equip your team with the tools and know-how needed to manage your inventory so you can focus on marketing, sales and other revenue-generating aspects of your business.

Need more information?

- Send Message: We typically reply within 2 hours during office hours.

- Schedule Demo: Dive deeper into the nuances of our software with Chelsea.

- Join Live Upcoming Webinar: New to Amazon inventory management? Learn three inventory techniques you can implement right away.

Start Your Free Audit

Start Your Free Audit