Amazon Inventory Management Training Guide

Basic to Advanced Guide For Sellers

Need to get better at managing your Amazon inventory but don’t know where to start?

Whether you’re a newbie or a veteran who has recently experienced a massive reduction in restock limits and therefore wants to reskill and adapt, this Amazon inventory management training guide is perfect for you.

In this guide, you’ll gain a deeper understanding of inventory management: how it works, the best practices, how to get started, and discover free resources to accelerate your learning and implementation.

Even better, I’ll empower you to create a plan and start implementing things that make inventory management more profitable. Maybe even enjoyable

In this Amazon Inventory Management Training guide, we’ll take a look at:

Why Learn Amazon Inventory Management?

There are two purposes for inventory management with one overall outcome in mind: avoiding stocking out and avoiding overstocking.

Those seem to be pretty obvious. But the overall main objective of inventory management is to maximize profits.

When you stock out, there is a lot of lost revenue and a lot of added cost involved. Overstocking causes the same thing and has even more damaging effects now with Amazon’s new restock limits and inventory structure.

There are many different things you can do to try to avoid those negative consequences. There are so many moving parts involved, and it can be pretty overwhelming, but when you break out the individual pieces, it becomes much more manageable.

Let’s start by talking about some of those moving parts and what they are to help you start moving in the right direction as you understand each piece.

How Does Inventory Management Work?

There are two main components to managing inventory, namely:

Inventory Visibility

You need to know where everything is, how long it takes to produce and move inventory from one place to another, and how to track it.

Forecasting

The other factor involved in inventory management is predicting future demand. How much future demand could there be based on past data and future plans? To predict future demand, use Amazon reports to gather data on your past sales for products that you have been selling. You also need to know information on new products like:

- What has been successful in the market?

- What are other similar products selling?

- How much in sales have those products produced at different times of the year?

Predicting future demand also means developing plans that consider your trends and your marketing plans.

- Are you trending upward or down? By how much? Over what period of time?

- Will you be doing a PPC campaign, listing optimization, or promotion?

- Will you have any email campaigns, Lightning Deals, or a promotion with influencers that could add a boost to your sales?

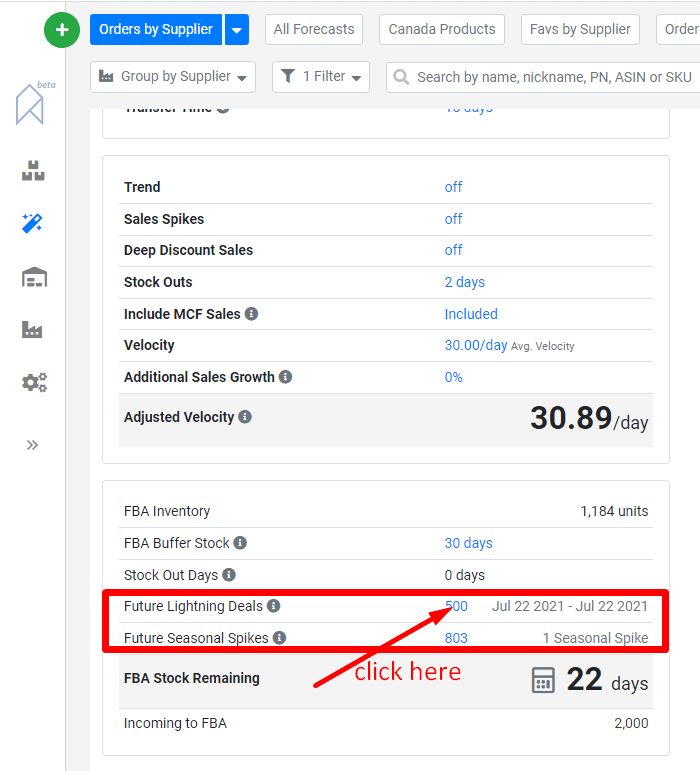

Other factors to consider including in your forecast data:

- Sales velocity for the past 30, 60, or 90 days, including seasonality. However, that data might not be relevant when moving into Christmas time, so you want to know what you did at the same time last year.

- Ordering or transferring frequency. Do you order every month or every three months? And how often do you transfer from your 3PL? Once or twice a month? Your sales velocity might change the amount that you order. If you order every month, you’ll have a smaller order than if you order every three months or every four months.

- Lead time and transfer time. How long does it take from the point that you submit your order to the time it arrives at Amazon? In SoStocked, we refer to a lead time as “the time from your supplier to the final destination.” And we like to refer to transfer time as “the point that you send your inbound inventory from your warehouse to the final destination.”

- Buffer stock. Buffer stock is an extra amount of inventory that you keep on hand to ensure you never run out. It’s like a cushion to account for unexpected things like shipment delays. You never want to run your inventory down to zero. You want to have that little extra cushion just in case anything goes wrong with your shipment or your check-in times so that you don’t stock out while you’re waiting for those things to resolve themselves.

- Marketing plans. Additional forecasting factors, as we mentioned before, are promotions, marketing events, and sales trends that you can add on top of your sales velocity. All of these factors have been built into the SoStocked tool!

See figure below:

Related How to Automate Amazon Inventory Forecasting For Accurate Reordering

How Hard Is Inventory Management?

Inventory management isn’t necessarily complex, but there are a lot of moving parts. If you can’t distinctly recognize each of the moving parts, it can be overwhelming.

But don’t worry! Below are some tips to help you navigate inventory management better.

Get back to basics

If inventory management seems complicated and confusing when you’re teaching or learning it, you need to cut back to the basics:

- Do you understand all of the different elements that are a part of this?

- Do you know all of the words and definitions?

- Can you duplicate everything before moving on to the next step?

Play to your strengths

Whenever you feel like something is confusing, it’s always a good idea to go back to where you felt like you were doing well.

More often than not, you’ll find something that you didn’t fully understand before you jumped into the more challenging thing. It’s important to study things on a gradient scale. If something’s feeling hard, you may have tried to jump too high on the gradient, and then you have to step back and return to the basics.

Vet your inventory data

Inventory management is like a math equation. If you leave out one variable, the entire answer is wrong.

For example, if the warehouse you work with has missing inventory on their report (it happens, they’re human!), they will report your inventory as too low. We’ve had our warehouse tell us they had less than they did, but we kept our own record in SoStocked so we could let them know that they had the extra inventory and needed to find it. And, of course, they did!

On the other side of things, your warehouse could say they have more inventory than they do, and that can put you into a stockout situation. You try to ship inventory that doesn’t, in fact, exist and then end up ordering too late and running out of stock.

As you can see, that’s just one example of how one wrong variable can either understock or overstock you.

Get better at embracing uncertainties

It’s impossible to predict 100% of what’s going to happen. No one could expect that COVID would occur or that some products would have their sales drop out and some products’ sales would skyrocket. No one can prevent stockouts 100% of the time, but you can get better at it. You can get more flexible in dealing with the issues that could come along.

A good inventory manager will equip you with the flexibility to solve those problems.

Part of the prediction process is working with your marketing team. Some of the biggest failures in inventory management happen when the marketing team is not working with the inventory team and not giving them the data needed by the inventory team. It is vital that the marketing team provide marketing plans to the inventory team in advance in order to vet out the inventory to ensure marketing campaigns won’t lead to stockouts.

The inventory team also needs to be more responsible for communicating with the marketing team and asking for those plans. The responsibility falls on both sides.

Additionally, the inventory team should be proactive in providing inventory data to the marketing team such as Stockout Risk Reports, Overstock Reports and Slow Seller Reports so that marketing can further focus on strategies to ensure their actions assist the inventory team in staying in stock and avoiding an overstock situation. More on these reports later.

It’s essential to create a way to coordinate your teams, production, warehousing, FBA inventory, and buffer stock. These elements working together will allow you to be flexible enough to mitigate problems like stockouts, improve your cash flow and maximize profits.

Is Inventory Management a Skill?

Inventory management IS a skill, but it’s a learned skill. And you have to know how to acquire it. You have to know what to learn. So, what are those skills that you will need to develop to be good at inventory management?

- Math. Find someone on your team that is good at math!

- Coordination. Very important but often overlooked.

- Prediction. The ability to use data and planning to predict what might happen.

However, if you have a lousy inventory management formula or method, all of these fundamentals won’t help you.

For example, if you aren’t looking at your numbers correctly or aren’t factoring in your stockouts the right way, you’ll end up stocking out again. All the skills in the world can’t help you if you’re working with insufficient data.

You must account for stockouts, filter out sales spikes that won’t occur again, and consider seasonality. You need to understand your product sales patterns and the elements of inventory management so that you can think with the data. Assign someone on your team who can think with the information and likes to evaluate data.

Download my free FBA Inventory Spreadsheet Template to give it a try.

The Art & Science Of Inventory Management

I think of inventory management as “The Science Of Past Data & The Art Of Future Planning.”

Your data comes from a couple of places, such as:

Inventory Data

Your inventory data includes knowing:

- Where it’s arriving to

- When it’s arriving

- How much you have

- Lead time

- Frequency of orders

- Sales velocity

Most of these should be set, but some data points are flexible. For example, how much stock you have is constantly changing.

Marketing Data

Stay on top of your sales plan, including answers to questions like:

- Are we working with a new agency that’s targeting to increase our sales with PPC?

- Are we doing a new email campaign?

- Are we doing a coupon discount push?

- Do we have plans to revamp our listings which could increase conversion rates?

- Are there other marketing plans in place that could affect inventory movement?

Cash Flow

Do you have the money to afford the inventory that you’re purchasing? If you don’t think you have the money or can’t make that payment, you might procrastinate and try to order late, which can get you into trouble. If you do need funding, you need to make moves to secure it on time.

We’ve talked about inventory and marketing working together. You also need to include your accounting team in some of these inventory decisions as well.

4 Top Amazon Inventory Management Training Resources

We’ve created a couple of different resources during the time we’ve worked with Amazon sellers.

I’ve been an Amazon seller since 2014, and I built the SoStocked software to solve my own inventory problems. I kept asking my friends in different masterminds what they were using, and I kept hearing that everyone was going back to spreadsheets because nothing was working right for them. SoStocked was born when I found out that people would rather use a spreadsheet than an inventory software! I wanted to solve the problem that everyone was dealing with.

For the first two years after launching SoStocked, I worked one-on-one with hundreds of Amazon sellers to help them with inventory management and the challenges that come with it. As we discovered the missing inventory management fundamentals common to most Amazon sellers, we built our software around solutions to these issues and created strategies to assist sellers in managing their inventory properly.

The following are some of the most vital resources to learning inventory management:

Inventory Mini-Course

For those of you using or interested in our software, we offer a free self-guided tour called the Inventory Mini-Course.

This mini-course consists of several different modules that walk you through setting up the SoStocked system. It also gives you an idea of how we’ve laid everything out within SoStocked, teaching you the system and defining things like:

- What is a lead time?

- What is buffer stock?

- How to build out a forecast?

- How to account for stockouts?

- How to develop advanced inventory calculations?

- What to do if you have a suspension?

- How are suspensions accounted for within the SoStocked system?

As you see how these things are built out, you will understand how you need to build out your systems, whether you use SoStocked or not. This mini-course will help you to learn the concepts and what procedures need to be in place for proper inventory management and forecasting.

But why DIY when you have a team of inventory experts who will meet with you one-on-one to get everything working?

When you become a SoStocked user, you’re entitled to a private one-on-one onboarding call with one of our inventory experts to help you set everything up correctly. We can also help you migrate your inventory data into SoStocked and get forecasting settings in place. This process allows you to put what you learn into practice, thereby accelerating your training.

Inventory Planning Webinars

Stay up-to-date on the latest Amazon inventory management trends, methods, and practices with my Inventory Planning Webinars!

I give Inventory Planning Webinars every two weeks covering various topics such as:

- What are the inventory planning basics?

- What are the best practices for inventory management?

- What is inventory-minded marketing and why is it important?

- How to apply inventory-minded marketing in your business?

- What are the advanced strategies that you need to use to prevent stockouts and overstocking?

- What are Amazon’s inventory policies, what do they mean, and how can I manage my business within these guidelines?

Knowing all this empowers you to move your systems towards improving your restock limits and general inventory management.

We also developed a modified version of these webinars. We call it “Work Party,” where you and your staff can get more of a head-on approach to inventory management.

In this webinar, you’ll learn how to implement the Standard Operating Procedures (SOPs) that our friends at Escala, a premium business consulting firm, helped to create. These SOPs allow you to lay the foundation for regularly running your systems like a well-oiled machine.

If you sit in on our Webinar Work Party, you’ll have the tools you need to build a workable, recurring system that keeps your inventory running smoothly and ensures that your marketing team gets the data they need and vice versa.

The webinar will also include inventory management SOPs and templates designed to help any new or continuing team member efficiently execute basic inventory management tasks on a regular basis, such as:

- Order Placement

- Shipping & Logistics

- Inventory Transfers

- Inventory Tracking, and more

Fundamental Training: SOPs and Blog Posts

Look to our essential Amazon inventory management training resources like SOPs and blog posts to supplement your study.

I mentioned the SOPs that we have available to keep your business running regularly. Reading through and learning those SOPs will help you to understand how your system should be running, how many people are involved, and who should be in charge of what.

We also address organizing and streamlining inventory in our training.

You can check out our blog posts on this and other topics related to inventory management. Organizing and simplifying inventory is all about how to keep track of everything and how to save money and time while you’re doing it. It includes order trackers and different reports to give you a better picture of what’s happening in your business so that you can take action steps to improve things, prevent stockouts or overstocking, or handle these issues if they’ve already occurred.

And then, we have inventory control.

Inventory control is all about getting those systems in, why to get those systems in, and what it means to your businesses financially if you do. For example, let’s say you have poor inventory habits like sending air shipments instead of ocean freight. Once you control your inventory and get good practices for inventory management in place, you could start saving some money. One of our users saved $150,000 per year once they figured out how to avoid those expensive shipments!

We also talk about techniques and best practices and how to get good at solving some of the most significant inventory issues like:

- What are the top issues that cause the biggest problems in my business?

- What are the solutions to those issues?

- What are the common denominators to these problems, and how do I fix them?

All of these solutions have been baked into SoStocked as well.

Advanced Tips and Techniques

Inventory-Minded Marketing

Your advanced training would include inventory-minded marketing and coordinating your inventory and marketing teams, which is extremely important, especially now. Marketers are responsible for a lot more now that all of the inventory in Amazon’s warehouses count toward the same storage-type restock limits.

Not only are they responsible for pushing best sellers and boosting revenue, but also for clearing excess inventory out of FBA warehouses to make way for better products. This concept should’ve always been part of any strategy but hasn’t been necessary until Amazon forced it with their restock limits policy.

Because of this, inventory-minded marketing becomes more critical than ever, as you need to make sure that your slow sellers are moving and converting into sales. You should also look into some advanced tips on preventing restock limits crashes when you experience an unfortunate stockout.

Pro tip: Download my Inventory-Minded Marketing Template to sync up your Inventory and Marketing teams.

Inventory Dashboards

Another crucial Amazon inventory management strategy is using Inventory Dashboards. When it comes to creating inventory dashboards, you are only as good as your data. And when your data is cluttered, and you don’t have a way to isolate the most critical parts, it becomes useless, and it’s easy to get overwhelmed.

To counter this, we’ve been able to create filtering, grouping, sorting, and hiding of columns so that you can build out custom reports. All of these reports can be changed and manipulated based on your needs.

Some of these reports include:

- Stockout Risk Report

- Overstock Report

- Slow Sellers Report

- Liquidation Report

- Inbound Shipments Report

All of these reports help you to simplify your data and to take action. If you don’t have these reports, you definitely should consider incorporating some or all of them into your weekly or monthly strategies for inventory and marketing plans.

Slow Seller’s Inventory Strategy

Another technique that I want to mention is the slow seller’s inventory strategy. This strategy addresses how to recover the cash sitting in your warehouse and the inventory that’s not moving and clogging up storage space and get it back working for your business. The idea is to turn that inventory from a liability back into an asset.

It’s not just a good idea anymore to move these slow sellers out to regain some of that capital. It has also become necessary because of Amazon’s storage-type restock limits.

This strategy will improve your cash flow, help you to put that money back into something that will make you more money, and prevent you from blocking your best sellers from being moved into Amazon FBA.

When slow sellers are taking up room, they’re not only dragging down your sell-through rate, which affects your IPI score, but they’re also affecting your utilization and excess inventory. Often this can all lead to your best-sellers being blocked, storage fees piling up, and lost opportunity costs due to stockouts.

Restocking Tips

I also want to touch on forecasting and restocking. If you have extended lead times, you must learn to forecast more accurately by doing six to 12 months’ worth of inventory forecasting. You need to understand what factors matter most and how to factor those into your equations.

Our advanced training addresses restock limits and strategies. Advanced restock methods include Min/Max Restocking, third party fulfillment and how to use inventory techniques to avoid stocking out and overstocking, bolster your storage limits, and improve your sell-through rate and IPI score.

Get Better At Amazon Inventory Management

Amazon inventory management training equips you with the best tools and techniques that you can use to gain better control of your top sellers, slow sellers, and new sellers. With proper training, you’ll be able to:

- Improve your inventory systems and processes

- Avoid stockouts and overstocks

- Maximize profits

- Enhance inventory visibility

- Become proficient at using software to streamline your data

- Predict future demand and calculate reorders more accurately

- Get your inventory, marketing, and accounting teams to work together effectively

Want to learn how to use SoStocked to make inventory management even easier? Sign up and work with our team 1-on-1 to get your inventory management, forecasting, and tracking dialed in.

Need more information?

- Send Message: We typically reply within 2 hours during office hours.

- Schedule Demo: Dive deeper into the nuances of our software with Chelsea.

- Join Live Upcoming Webinar: New to Amazon inventory management? Learn three inventory techniques you can implement right away.

Start Your Free Audit

Start Your Free Audit