How Amazon Reserved Inventory Impacts Your FBA Business

Managing Amazon Reserved Inventory

Is your top seller almost out of stock, but Amazon won’t let you send in more? 😫

It’s no secret that Amazon warehouses are overwhelmed right now due to a sharp uptick in online orders fueled by the pandemic, leading to increased inventory restrictions.

For instance, some sellers cannot create new shipment plans even though they’re still eligible for restock. One possible explanation is that Amazon counts the following against their storage limits:

- Inbound shipments or unused plans

- Reserved inventory, e.g., units in fulfillment center transfer, or units in processing status

- Current pending orders

For that reason, affected sellers find themselves stuck shipping their additional inventory to third-party warehouses instead of FBA.

So if you can’t send more stock into FBA for some reason, consider looking into your reserved inventory levels as a potential blocker. 👈

In this post, we’ll take a deep dive into Amazon reserved inventory and discuss ways to manage it so you can improve your storage limits.

In this Amazon Reserved Inventory guide, we’ll take a look at:

What Does Reserved Mean in Amazon Inventory?

Inventory in reserved status is stock in the process of being transferred between Amazon warehouse locations or currently sidelined at a fulfillment center for further processing, this can include customer orders, units being checked into fulfillment centers or units being checked out of fulfillment centers.

Products being shipped to another fulfillment center are still available for purchase with the message “In stock soon” and sometimes include the date the inventory will be back in stock.

3 Reasons for Reserved Status

- Customer Orders: Some of the inventory in Reserved status are used to fulfill customer orders.

- Fulfillment Center (FC) Transfer: This status means products are being shipped from one warehouse location to another to put them closer to customers, which allows for one-day or two-day shipping. FC Transfer products are available for purchase, but customers might receive a back-ordered message along with the estimated arrival date if there are no other items available for immediate fulfillment.

Transferring usually takes 1-5 days but can take up to 30 days. - Fulfillment Center (FC) Processing: Units in FC Processing status have been set aside at the fulfillment center to check in, verify product authenticity, weight and dimensions, among other additional FC processing requirements. This process usually takes two working days on average unless there’s a potential problem that requires further investigation, but it can also take longer if the fulfillment center gets backed up and overwhelmed with too much inventory.

It is important to note that inventory that is being processed in or out of a fulfillment center may be marked as both FC Transfer and FC Processing.

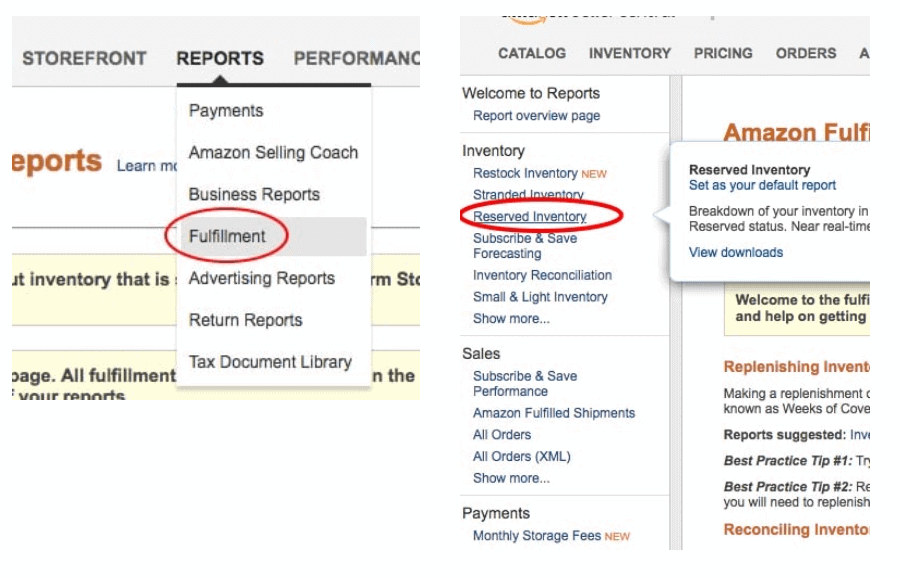

Where To Find Your Amazon Reserved Inventory Levels

You can check your Amazon Reserved Inventory Levels by doing the following:

- Log into your Amazon Seller Central account.

- Visit “Reports.”

- Under “Inventory”, click on the “Fulfillment” button.

- Then, go to “Reserved Inventory.”

- You can then access your daily Reserved Inventory reports.

How Does Amazon Reserved Inventory Affect Your Bottom Line?

It’s important to pay attention to your FBA reserved inventory because it affects your utilization.

As mentioned earlier, many Amazon warehouses are operating at full capacity, so, to ensure they don’t overcrowd their facilities, they have resorted to counting your reserved inventory against your restock limits.

Suppose you have an inventory limit of 1,000 and sold 500 units in the last five days, but Amazon only shipped 150 of those. The inventory that has been sold but unshipped would be 350 units.

In that case, your available max ship quantity could be calculated as 1,000 minus whatever you have at FBA unsold, let’s say it’s 400 units, plus 350 unshipped customer orders. That means the inventory that you will be allowed to ship in based on your restock limits would only be 250 units due to your reserved inventory.

Restock Limit – Unsold Units – Unshipped Customer Orders = Max Ship Quantity

$1,000 + $400 – $350 = $250

You would only be able to send in the 350 units you’ve already sold because those units are stuck in reserved status waiting to be shipped out.

If you look into the Restock Limits by Storage Type FAQ, you’ll see that Amazon claims that Reserved inventory is not included in utilization, but we have found this not to be the case. FC Transfer and FC Processing appear to be included in utilization.

Restock Limit – Available Inventory at FBA – Open Shipments – (Reserved Inventory – Customer Orders) = Max Ship Quantity

If you can’t replenish stock due to maxed-out storage limitations, it tends to increase your stockout risk.

And as you already know, going out of stock on Amazon hurts your ranking, sales, IPI score and restock limits. Therefore, keeping an eye on your inventory levels is crucial.

6 Tips To Manage Your Amazon Reserved Inventory Levels

Utilize Your Storage Space Correctly

Reserved inventory is one of the influencing factors that affect your utilization percentage. A high utilization rate usually indicates storage clogged with pending orders requiring additional processing due to authenticity, sizing, payment issues, slow sellers, stranded items, or excess units that aren’t making as many sales as your top sellers.

And for that reason, Amazon isn’t going to want to give you more storage space until you get your inventory levels back to a healthy range.

Curious about your utilization rate? Use this formula to calculate it:

Utilization Quantity ÷ Restock Limit x 100 = Utilization Percentage

– or –

Available Inventory at FBA + Reserved Inventory – Customer Orders + Open Shipments + Restock Limit x 100 = Utilization Percentage

To find these numbers, follow these steps:

- Go to your Inventory Dashboard.

- Open the “Inventory Performance” tab.

- Click on the “Restock Limit” button.

- Find your “Utilization Quantity” and “Restock Limit,” also known as “Maximum Inventory Level.”

Ideally, in a perfect world you’d want to maintain a 30% utilization rate as it indicates excellent sell-through and turnover rates, which boosts your IPI score and storage volume limits. Generally a 30% utilization should mean that you are turning over your inventory monthly as Amazon should be awarding you 3 months worth of storage space so a 30% utilization would indicate about a monthly turnover.

However, with Amazon reducing restock limits so drastically, many sellers are finding that they are forced into being maxed out which has made it very hard for some to even maintain an 80%-90% utilization.

But, if you are lucky enough not to have your restock limits cut down too much, you may have been able to keep a good utilization percentage by selling through inventory at a good rate which tends to warrant Amazon to grant you more storage space so you can sell more through FBA.

Related: Determine your inventory turnover ratio by following the steps outlined in this article: Amazon Inventory Turnover: Understand, Calculate, and Automate

Get Your Inventory Checked In Faster

Slow shipment of your inventory into FBA warehouses can do significant damage.

Amazon usually takes up to a week to process your FBA inventory, receiving it, transferring it to other fulfillment centers, and stocking it for sale. But with COVID and warehouse labor shortages causing significant delays, expect a much longer check-in process.

Customers should still be able to buy your reserved products during that time, but they might be shown a “Back-ordered… Due in stock + estimated in-stock date” message.

If customers can’t get their orders within one to two days, it could affect your conversion rate, i.e., they would leave your page, which means lost sales.

Try to get your inventory checked in faster by using UPS Freight. They have a standing agreement with Amazon that lets them ship in goods whenever there is a gap in the schedule.

A gap in the schedule forces Amazon to reach out to UPS Freight and request them to send any extra stock they have to complete an order immediately. And because of that agreement between the two companies, checking in your FBA inventory tends to be faster.

Another method would be to send some inventory into Amazon by small parcel delivery (SPD). SPD is loose cartons rather than pallets that have to be broken down so those shipments tend to have a much faster check-in time as well.

By checking in your inventory quickly, you can avoid stocking out and fulfill orders immediately while keeping your reserved inventory levels low.

Create a Removal Order

If you need to free up space quickly or have been unsuccessful selling through stale inventory, creating removal orders sometimes becomes the only option for improving your storage capacity.

By creating a removal order, you’re freeing up some storage space that you can use for better products that are less likely to end up in a reserved inventory list because of product issues. For example, the product is flagged as inauthentic, requires investigation or is too bulky and requires extra processing.

Should you decide to remove inventory from FBA, follow the steps below:

- Go to Manage Inventory, click the “Edit” drop-down list, and select “Create a removal order.”

- On the “Removal Order details” page, go to “Method of Removal”, choose “Return to Address,” and then type the complete address that you want your items delivered to.

- Create a removal order ID or allow it to be automatically generated and specify the quantity of fulfillable and unfulfillable units you want to remove.

- Review and submit your removal order.

It is important to know that when inventory is in Reserved status, there’s nothing you can do but wait for it to become available or “fulfillable” again and before removing it. Only then can you create a removal order to have Amazon return that inventory to you or your warehouse.

Pro tip: Note that removal orders don’t increase your sales velocity or boost your restock limits. They’re just an excellent way to clear up space. If you’re a SoStocked user, you may want to disable them from your “Orders” page so you can get the most accurate sales data possible. Click here to find out how to disable removal orders from your sales velocity in SoStocked.

Use FBM

Prepare for stockouts, especially during sales seasons, by setting up a third-party fulfillment center. Having a backup warehouse ensures your Amazon restock limits don’t suffer, as you’ll be able to switch from FBA to FBM immediately. Amazon’s restock limits algorithm recognizes FBM sales as part of the sales velocity that contributes to restock limit evaluations.

Plus, if FBA won’t accept your additional shipments, you can send them to your warehouse and ship orders from there. That way, you won’t get stuck unable to sell or fulfill if you have trouble getting inventory into FBA.

Related: 3PL Logistics Backup for Amazon

Slow Down Velocity

This option is not ideal but is sometimes a necessary tool for sellers who want to avoid a short-term stockout and can quickly regain their lost rankings. But even eight-figure earners struggle with slowing down their velocities, so proceed with caution and watch that your page rankings drastically drop.

You can lower your sales by:

- Slowly increasing prices. Amazon as well as long-term, repeat customers do not like to see a sudden, large price increase. Therefore, increase pricing slowly and incrementally. If you increase prices too quickly, Amazon may suspend your listing until you fix what they call a “pricing error”.

- Easing up on promotion. Consider removing aggressive PPC, active coupons or deals for a few days. While promos are excellent tools for boosting your conversion rate and sales, it is meaningless if your products are unavailable to customers.

Slowing down your velocity should only be an option when you can prevent a stockout as it will help your IPI score and In-Stock Rate to avoid stocking out. Otherwise, most smart marketers advise increasing sales and going out big to increase page rank before any inevitable stockout. If you know you’ll be out of stock for a bit, this may be the better option.

Remember to restore everything to normal once you’re able to send inventory into FBA again including any paused marketing or price changes.

Related: Marketing On Amazon: Increase Sales and Decrease Stockouts

Remove Unused Shipping Plans

Like Amazon Reserved inventory, inbound shipments also impact your utilization percentage. If your utilization is higher than average, you might have some unused shipping plans open.

The sooner you delete those inbound shipments, the better because Amazon likely includes them in calculating your sell-through rate, which is the most critical inventory KPI for Amazon and which is a rolling 90 days. Those open and unused shipments, then will carry over for the next three months as part of your average utilization, impacting your Sell-Through Rate negatively.

While Amazon doesn’t charge a fee for overutilization (yet, who knows what they may do in the future), you can’t inbound anymore stock if you’re above your restock limit.

So go ahead and delete any unnecessary inbound shipments right away. If you can’t delete them, contact Seller Support and ask them to do it manually for you on their end.

Related: Check out the “Key Metrics” section in this article to see why it’s important to understand your sell-through rate and to determine what data Amazon uses to calculate it.

Improve Your Storage Limits With SoStocked

One of the effective ways to maintain your restock limits is to stay in stock.

But stocking out has become quite the norm over the last few months as sellers haven’t been able to ship their inventory into FBA. Because of supply chain issues, new inventory restrictions and slow check-in times, sellers have struggled with significant delays resulting in lower in-stock rates, adversely affecting their IPI scores and restock limits.

Good thing SoStocked is equipped with the following features that can help you to avoid stockouts.

- Inventory Timeline: Use the inventory timeline to track inventory levels and to build out your future marketing plans to determine when you’re going to need to restock to avoid stockouts. It also helps you detect any gaps in your transfer schedules so you can adjust them accordingly.

- Advanced Stockout Calculations: This feature allows you to identify and account for sales velocity anomalies such as significant drops or spikes in your average sales, which could be due to a massive sales campaign, stockout or listing suspension.

- Min/Max Restocking: Set and automate a buffer stock and max stock system that will alert you to send in additional inventory well before you stock out. That way, even if FBA is taking ages to check your shipment in, you’ll have enough stock to keep potential stockouts at bay. It’s also best practice to keep a safety stock for your backup warehouses.

Using SoStocked’s max stock setting will keep you from sending in too much inventory to keep you from overstocking at FBA. - Factor out Blackout Days: National holidays in your suppliers’ country lead to temporary factory closures and shipping delays. To avoid ordering or transferring too late, use the Blackout Days feature to factor factory and warehouse closures such as Chinese National Holiday and Chinese New Year into your forecast calculations. You can also download our Blackout Calendar to help you easily identify some of the most popular blackout dates.

Be sure to communicate with your suppliers in advance to be sure you have all of their closure dates accounted for and can plan accordingly. - Overstock Report: Overstock Inventory happens when there’s an oversupply of inventory versus demand. When you have products that customers don’t want, they end up stuck in FBA, taking up storage space. In SoStocked, you can quickly analyze your sales patterns to identify slow-moving items that might create an excess inventory situation. Then, you can then tag them and sort them into categories, such as “Marketing,” “Liquidation,” “Removal,” or “Disposal,” so you’ll know which inventory to get rid of. Eliminating excess inventory clears up storage space that you can use to stock more of your top sellers.

Bonus: Join me in my live webinar to discover key storage-type inventory strategies that you can incorporate into your inventory planning. Sign up here!

Keep Your Amazon Reserved Inventory Level Low

Now that you understand how easy it is to max out your utilization with Reserved inventory (and unused shipping plans), you can use the tips in this article to restructure your operations to minimize these issues. If Amazon has been taking weeks to transfer or check in your inventory, and you’re having trouble sending in more stock during this time, send inventory to third party fulfillment center and switch to FBM.

But if you are trying to avoid this as much as possible, my advice is to evaluate your sales across your entire catalog and prioritize your products based on velocity and profitability. Check out our new Restock Limits tool which was designed to do just that.

Lastly, consider removing stale inventory from FBA to allow you to bring in more inventory of your best sellers so you can avoid stockouts due to excess inventory.

Keeping an eye on all aspects of your inventory has become more important than ever. Having systems and contingency plans in place will help you to navigate the storms that come with an Amazon business.

Need more information?

- Send Message: We typically reply within 2 hours during office hours.

- Schedule Demo: Dive deeper into the nuances of our software with Chelsea.

- Join Live Upcoming Webinar: New to Amazon inventory management? Learn three inventory techniques you can implement right away.

Get Started

Get Started